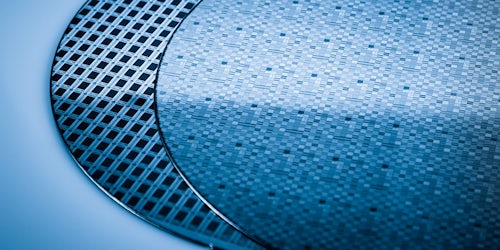

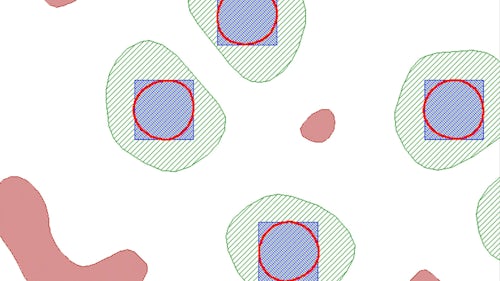

Automated context-aware IC design verification can solve demanding design and manufacturing challenges in both established and emerging process nodes. Capabilities such as automated voltage propagation, voltage-aware design rule checking, and integration of both physical and electrical information within a logic-driven layout framework helps designers ensure the performance and reliability of complex IC designs within today’s tight delivery schedules.

Fast, accurate, automated context-aware checking in all phases of IC design verification

Automated context-aware checking has become an essential best practice for providing reliable and timely IC chips to the market. Designers can leverage the actionable net/device debug information in error results to more quickly and easily adjust layouts based on both the electrical and geometrical features in an IC design, improving both verification precision and debugging efficiency. Physical, circuit, electrical, and reliability IC design verification can all take advantage of context-aware checks to improve the quality and accuracy of results, while reducing turnaround time.