Embedded devices and connected products are changing product design methodologies, and this change is compelling more and more companies to take advantage of the digital twin, augmented reality, and virtual reality in engineering.

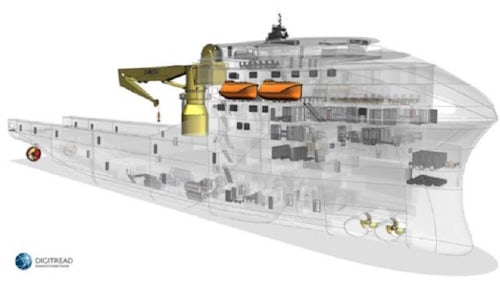

By bringing the virtual world and the physical world together, new insights allow for a continuous loop of product and production optimization. Using virtual reality to visualize products throughout their development lifecycle encourages innovation and minimizes rework.

Watch this video from a previously recorded webinar to discover how product lifecycle management (PLM) software with visualization technology empowers users to take insights from the virtual world and realize innovations more quickly and more reliably with fewer prototypes.

This video series covers a range of topics highlighting the capabilities and benefits of PLM software:

- What is PLM software

- Better engineering collaboration

- Virtual reality in engineering

- Multi-discipline BOM management

- Cloud-based PLM

Developing connected products using PLM with visualization technology

Engineers are incorporating electronics, electrical systems, and software, in addition to mechanical product designs, to meet the demands of smart, interconnected products.

This shift to more complex designs is fraught with challenges brought on by interconnected parts. Making sense of everything is made easier with PLM software like Teamcenter and Teamcenter X.

Read this ebook by Lifecycle Insights and explore the key technology enabling companies to see past the complexity and innovate faster: PLM benefits of the digital twin and the digital thread for smart, connected product development

Get started with Teamcenter X product lifecycle management software

Teamcenter X is a flexible, modern PLM software suite that can be delivered as a service. Start your own digital thread to connect every stakeholder and process throughout your product’s lifecycle.

Teamcenter X adapts to meet your unique needs, and it’s designed to grow and change with your business.

Take Teamcenter X for a test drive, and find out if it’s right for your business.