Speeding up the process of identifying the most promising designs for turbines

Siemens Energy uses Simcenter and artificial intelligence to improve efficiency, sustainability and cost-effectiveness

Siemens Energy

Siemens Energy in Berlin develops innovative solutions, including gas turbines, renewable energy technologies and green hydrogen production. They create products and services for conventional and renewable power generation, transmission and storage. It also houses an electrolyzing factory for green hydrogen production and a facility for testing and refurbishing gas turbine blades.

https://www.siemens-energy.com/global/en/home.html

- Sede:

- Berlin, Germany

- Produtos:

- Simcenter HEEDS, Simcenter 3D software

- Setor industrial:

- Aerospace & defense, Energy & utilities

We would never be able to create and manage this amount of data and ensure it remains in a consistent and readable format without Simcenter HEEDS and this workflow.

Driving robust design

In a major project co-funded by the German government, Siemens Energy Berlin is using Simcenter™ software simulation technologies and artificial intelligence (AI) to find ways to optimize turbines. Using Simcenter and AI is enabling the team to improve efficiency, accelerate design cycles and optimize performance in multiple disciplines, including enhancing aerodynamic design and mechanical integrity.

“The key goal at the beginning of the project was to fully understand a design so we could make every component as robust as possible and predict failure before it happened,” says Jason Abdallah, AI program manager at Siemens Energy in Berlin.

Incorporating AI enables the team to run many optimizations in a short amount of time so they can explore the effect of material combinations or deviations that may affect the design.

Furthermore, using AI also helps to test and validate all aspects of the computer-aided design (CAD) model, including how components interact. Consequently, the team scans every component to resolve uncertainties regarding temperature or casting.

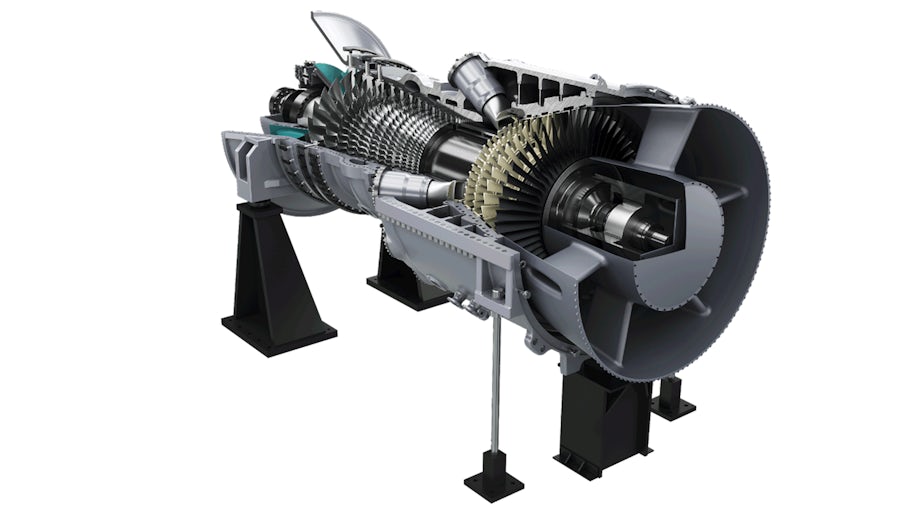

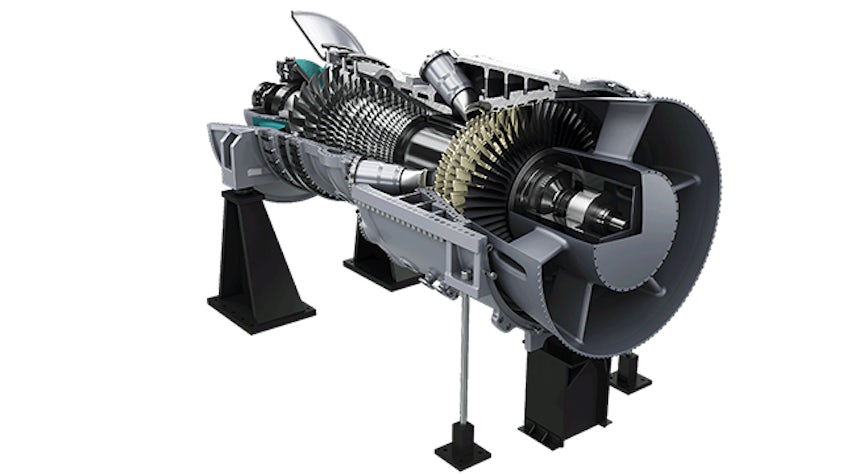

Siemens Energy SGT5-9000HL gas turbine.

Continual development and enhancement

This approach is designed to improve the efficiency of existing machinery and enhance the design of new turbines. Therefore, the project includes monitoring the status of the blades and vanes within active machines in the field. If defects such as distortions or elongations are identified, the team can run simulations using the existing design to predict if or when failure is likely to occur and then use the field data to improve the robustness of the design.

For example, the data gained via the sensors on existing machines contain the information the team needs to describe the thermal boundary conditions for a model that can be tested for mechanical integrity, enabling the team to predict life expectancy.

Expanding the design space

Until now, the models could be used to predict phenomena such as stress, strains and displacement, but the model relied solely on the data it was trained on; it does not have any understanding of the physics behind it. This limitation means that learning cannot be transferred to another model.

The aim of the next stage is to use AI to create more complex, transformer-based models, neural operators or even foundation models that can learn and transfer learning from one set of training data to another.

The goal is to not only be able to transfer learning between blades, but also between blades and other components.

Until recently this has not been possible due to computation time and capacity constraints. This led to a bottleneck in the design process around mechanical integrity – computing aerodynamics and heat transfer.

The AI loops allow the team to explore a much larger design space by changing boundary conditions and identifying promising candidates for further design development, which speeds up verification.

Essentially, the use of AI allows the team to explore more design possibilities within a vastly shorter timeframe.

-640x360.jpg?auto=format,compress&w=843&q=60)

A holistic approach to gas turbine engineering.

Relying on data

Using AI enables the team to evolve from a design that is centered on computation to a design that is centered on data.

“With AI once the team has trained the model with the relevant data, which takes six to 12 hours, they are able to complete the equivalent of those 2,000 runs in minutes,” says Abdallah. “Depending on the complexity of the computation, previously it could take from one to seven days per run, which even on a grid with many CPUs adds up to months for 2,000 runs.”

Integrating AI optimizes the design process by reducing the amount of time and resources wasted in pursuing dead ends. It makes it easier and faster to identify new opportunities for optimization, which previously would have been too resource-intensive to investigate or may have remained “unknown unknowns.”

Although each test generates additional data on which to train the model – even though accuracy per simulation may be slightly lower – the uncertainty diminishes because the design space is much larger.

-640x360.jpg?auto=format,compress&w=843&q=60)

Seamlessly integrating AI into the design workflow.

Creating AI methodologies

Having tested and validated the AI integrations and the code written specifically for the team’s design use cases, Abdallah’s first objective for the next stage is to create user-friendly methods and a learning path for those new to AI.

“There’s a lot of enthusiasm among our engineers to work with AI,” says Abdallah. “But many have no experience in using this new technology. The challenge we’re facing is to provide a clear, user-friendly path for colleagues to develop their skills and confidence in using AI.”

-640x360.jpg?auto=format,compress&w=843&q=60)

Predicting of the results of the full FEA simulation (elastic-plastic and viscoplastic behavior).

Achieving faster and more robust design

Siemens Energy is collaborating with the simulation experts at Siemens Digital Industries Software to develop and build an efficient, bespoke toolchain to handle all processes.

With Simcenter it’s easy to integrate in-house code and scripts for specific analyses, such as postprocessing stresses, assessing mechanical integrity and integrating Simcenter STAR-CCM+™ software and NX™ software for CAD and heat transfer analysis in the overall toolchain. Siemens Energy also used Simcenter 3D™ software, the comprehensive, fully integrated computer-aided engineering (CAE) solution.

Simcenter and NX are part of the Siemens Xcelerator business platform of software, hardware and services.

-640x360.jpg?auto=format,compress&w=843&q=60)

Dataset composition: Venn diagram showing parameter variations across wall thickness (122), temperature profile (108), geometric stacking/rotating (118) and combined variations (324).

Efficient data management

Using Simcenter also provides a highly efficient and reliable way to monitor the toolchain and refine the extensive amounts of generated data.

It can be used to place error analysis that automatically deletes data outside the set parameters, reducing the data load by 25 percent or more.

This can increase efficiency by helping the team rapidly identify the best candidates for optimization.

By setting parameters and error analysis, Siemens Energy has been able to create a toolchain that covers all aspects of the simulation. The team was able to run a chain for more than 65 days. It remained stable throughout and delivered over 1,000 data points for training the AI.

“Creating massive opportunities for improving the aerodynamics and changing the geometry of the air foil to meet changing temperatures is a huge success for us,” says Abdallah. “We were also able to increase the design space to have more capacity to combine data from the field with previous simulation data to train the models.”

Leveraging Simcenter HEEDS

Initially the AI code was created outside of the Simcenter chain. As Siemens Energy moves forward, the scripts will be included in Simcenter HEEDS™ software. Further, the team will also build in additional automation.

All data is managed in the Simcenter tool-chain, and the size of models can be adjusted as necessary to provide the most efficient balance between accuracy and model size.

Siemens Energy developed a process for managing and storing data for later use by converting them to HDF5 files.

The HDF5 files are available internally for training purposes and making predictions with Simcenter.

“We would never be able to create and manage this amount of data and ensure it remains in a consistent and readable format without Simcenter HEEDS and this workflow,” says Abdallah. “Boundary conditions can be recorded so you can track, say, the source of a rise in temperature to train the AI in years to come.”

-640x360.jpg?auto=format,compress&w=843&q=60)

Enhancing design robustness: AI-driven exploration of design space to improve component service life and structural integrity.

Supporting sustainability

With this structured resource of consistent, verified data, the team can confidently integrate AI into their simulations to accelerate and extend capabilities to create and optimize new materials.

Siemens Energy uses analysis generated by a digital twin to be confident they are delivering a stable, highly efficient turbine that can be relied on for consistent power output.

Further, this makes it faster and easier to test and achieve more sustainable, climate-friendly solutions for power generation – for example, by increasing the use of hydrogen.

Pre-empting issues

Siemens Energy is also using AI in other areas, such as scanning for crack detection. After a field issue, service or coating depletion or a period of operation, the team opens the machine and inspects the blades to check on the status.

The team also runs the video inspection through the AI. The AI postprocesses everything and can discover if the blades have been spoiling, or if there are cracks or other issues. By postprocessing or preprocessing the data, the team knows that certain changes will lead to issues.

They can use this data to train the AI and avoid or design out such issues. For example, by turning off the machine in the field before any damage is done or using the information to schedule periodic maintenance before cracks occur.

-640x360.jpg?auto=format,compress&w=843&q=60)

Transformer solver model predictions versus actual values: creep strain (left) and von-Mises stress (right).

Government investment in the project

The German government’s funding of 30 to 40 percent of the project has been critical in supporting the work to develop and extend these new technologies and has enabled Siemens Energy to continue to invest in new tool design and code development. Funding was provided by the Federal Ministry for Economic Affairs and Energy (BMWE) reference 03EE5077A Project 3D-ML-Creep.

Supporting a complex, high-risk project

In the early days the team found people were skeptical of the potential value of using AI in turbine design and optimization. But since presenting a paper with the initial results of their work in late 2023, they have overcome this skepticism and are pushing forward.

The next goal is to discover whether they can transfer learning from one area of physics to another.

“The datasets we create for one design can’t be used in another area,” says Abdallah. “Our focus is to develop solutions that allow us to transfer learning and test data for use in multiple areas of inquiry, as well as integrating knowledge and data gained in the field.”

Collaborating for the future

Working in close collaboration on this project has been highly beneficial for both companies, notes Abdallah: “With their software experience and expertise, the Siemens simulation team has been able to sort out many issues for us. It’s been good to have them onboard, and we are looking forward to continuing our close collaboration.”

Part of the excitement of the project for both teams is they are exploring unknown territory, which means they must develop the necessary tools to ask the right questions so they can find critical answers.

With their software experience and expertise, the Siemens simulation team has been able to sort out many issues for us. It’s been good to have them onboard, and we are looking forward to continuing our close collaboration.