Shortening thermal test cycles and improving circuit board designs to meet thermal reliability requirements

KeenusDesign uses Simcenter Micred to test electronics nondestructively for thermal properties early in development

KeenusDesign

KeenusDesign manufactures and sells temperature control devices for thermal testing of electronic equipment. The company is an expert in temperature control and solving problems of thermal testing and measurement in new areas of design where there is no existing test solution.

- Sede:

- Higashiyamato-shi, Tokyo , Japan

- Produtos:

- Simcenter Micred T3STER hardware

- Setor industrial:

- Electronics, Semiconductor devices

We are asked for difficult or unfamiliar measurements every day, so the quick response we get from Siemens is a great help.

Needing thermal reliability

Innovative designs for electronics and power electronics are evolving quickly and often bring thermal challenges. When devices are subjected to high or fluctuating temperatures, they are more likely to fail.

This is particularly true in the automotive industry. As auto designs move towards electrification, the need for thermal testing power electronics is greatly increasing. Additionally, reliability standards are strict in the automotive industry; thus, manufacturers need to ensure their electronics meet challenging thermal reliability requirements.

However, KeenusDesign has found a solution by providing the necessary tests to validate the performance and reliability of power electronics.

KeenusDesign, founded in 2006 by Junichi Tachibana, a mechanical design engineer, expert in robotics and measuring instruments and representative director, manufactures and sells temperature control devices for thermal testing of electronic equipment. The company excels in temperature control and solving testing and measurement problems in new areas of design where there is no existing test solution. Tachibana knows exactly what various manufacturing companies need.

“In vehicle electronics, the quality standards are the highest, so there is a greater requirement for testing,” says Tachibana. “For example, if a customer has been making cameras for consumers, the thermal testing requirements are not severe. But if they are selling to an automotive manufacturer, they have a new requirement for thermal reliability testing with higher quality expectations.”

-640x360.jpg?auto=format,compress&w=843&q=60)

Using Simcenter Micred to power thermal testing

To power thermal testing for their customers, KeenusDesign turned to Siemens Digital Industries Software, leveraging Simcenter™ Micred™ hardware, which is part of the Siemens Xcelerator business platform of software, hardware and services.

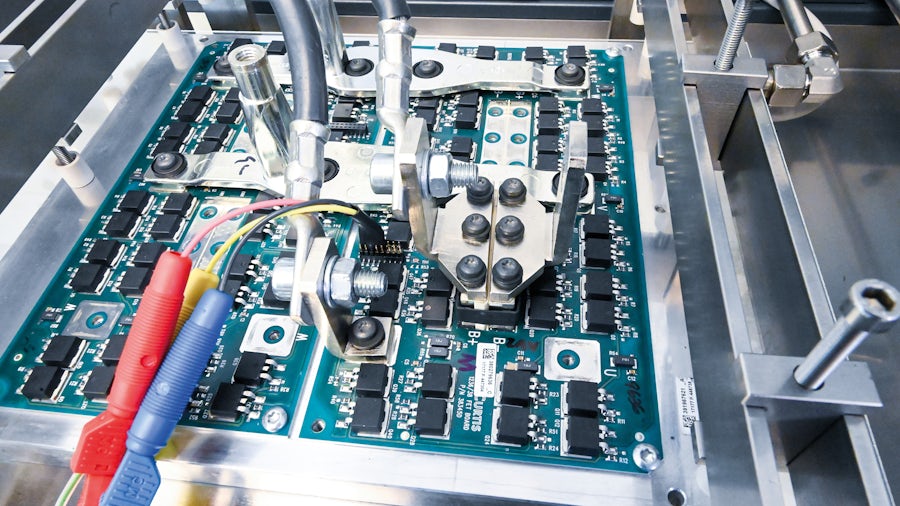

Specifically, KeenusDesign performs thermal tests using Simcenter Micred T3STER™ hardware for transient thermal resistance measurements and Simcenter Micred Power Tester hardware for power cycle test equipment. These systems allow KeenusDesign to perform tests with high accuracy, speed and repeatability. The decision to use Simcenter Micred T3STER was simple.

“Leveraging Simcenter Micred T3STER is the only instrument capable of measuring thermal resistance with this high of precision using the static method,” says Tachibana. “We know about the competing products, but they were never an option.”

Traditionally, during the research and development (R&D) phase for circuit boards and semiconductors, manufacturers create prototypes that they test until failure by switching the power on and off. They then take the prototype to a laboratory to investigate the reason and location of the failure. However, these methods are destructive, meaning engineers take apart the prototype and cannot always separate the failure’s cause and effect.

Tests conducted with Simcenter Micred are purely electrical, so they are completely nondestructive, meaning there is no need to cut a product open to test the layers of electronic components inside. Using Simcenter Micred Power Tester hardware and software combines active power cycling with monitoring of thermal and electrical degradation, making it easier to know a failure’s cause. Additionally, since engineers do not need to manually take the prototype apart afterwards, using the Simcenter Micred method also shortens testing time and workloads considerably.

“Siemens products are the de facto standard in Japan and have tremendous credibility,” says Tachibana. “We have earned our customer’s trust by using this equipment.”

As a result of its reputation and position in the marketplace, many well-known Japanese companies require their suppliers to use Simcenter Micred.

-640x360.jpg?auto=format,compress&w=843&q=60)

Adding value for a complete thermal testing solution

KeenusDesign knows its customers well and provides additional value to its thermal testing solutions by designing and building thermostatic test chambers and temperature control stages that combine with the Simcenter Micred testing hardware.

The company had been using a jig for thermal tests from -40 degrees Celsius (°C) to 150°C until a customer asked them to customize the jig to obtain measurements for JEDEC and JESD51. Other Simcenter Micred T3STER users who needed the same level of thermal testing soon wanted the same solution, as well as ones for Automotive Qualifications Guidelines (AQG) or Automotive Electronics Council (AEC) standards. Eventually, KeenusDesign released a jig for the Simcenter Micred Power Tester.

“We listen carefully to our customers to understand the measurements they need, and if they cannot obtain them with a conventional solution, we use our unique equipment and jigs to solve these challenges,” says Tachibana.

These jigs allow for the combined system to measure the thermal performance of devices at temperatures ranging from -55°C to 250°C.

-640x360.jpg?auto=format,compress&w=843&q=60)

“Our jigs are used to build environments for tests with high repeatability in accordance with standards,” says Tachibana. “We are working on solving measurement-related issues that are difficult to solve with other equipment.”

KeenusDesign uses Simcenter Micred T3STER and Simcenter Micred Power Tester in several ways. As they recreate the customer’s environment and build the jigs for thermal measurement, they gain a better understanding of the engineering challenges around heat. Thermal test data identifies potential weaknesses in a design and provides the metrics they need for quality control and technical documentation.

Adding robotics helps speed up testing, especially when power cycle testing needs to run for several weeks. Additionally, KeenusDesign can add monitoring that shows how to improve a design.

-640x360.jpg?auto=format,compress&w=843&q=60)

Providing thermal testing services

KeenusDesign sells Simcenter Micred systems. However, some customers who need thermal testing cannot buy their own test system, so KeenusDesign decided to offer thermal testing and power cycle testing as a service. These thermal testing services are ideal for customers who do not have enough equipment and engineering resources to run their own tests. Some do not conduct any thermal testing at all, and others use simple thermocouple-based measurements, which are not sufficiently accurate for some industries.

“Transient thermal resistance measurements are necessary for power semiconductor manufacturers and certain manufacturers who need to understand the thermal resistance of their products, such as the circuit boards where the semiconductors are mounted,” says Tachibana.

KeenusDesign generally performs power cycle tests during the product’s development stage. Demand for these tests is high and growing, especially for in-vehicle applications, and some customers are considering buying Simcenter Micred products. By providing test services, KeenusDesign can demonstrate the equipment.

Additionally, the company can leverage its knowledge of customers’ requirements to develop a portfolio of advanced services based around Simcenter Micred T3STER and Simcenter Micred Power Tester.

”It is the results that customers need, not the test environment,” says Tachibana. “The bureau-desk-type Simcenter Micred Power Tester is designed to fix and cool samples, but depending on the test’s objective, it may be over or under spec, so we modified the Simcenter Micred Power Tester to suit specific tests and provide an optimal, efficient test environment for our customers. We find we can use this to help our customers when our competitors cannot.”

With the specialized equipment and the knowledge gained from their testing work, KeenusDesign has become one of Japan’s leading consultancy for thermal characterization, serving the country’s most important manufacturing companies.

“We aim to provide cutting-edge solutions that enable our Japanese customers to succeed and become top players in global markets,” says Tachibana. “Since all our customers are world-class businesses, they demand safe and accurate measurements, and it is important that we have a way to achieve this.”

Additionally, KeenusDesign enjoys close involvement with Siemens’ sales, engineering and support teams. “We are asked for difficult or unfamiliar measurements every day, so the quick response we get from Siemens is a great help,” says Tachibana.

-640x360.jpg?auto=format,compress&w=843&q=60)

Planning for the future

KeenusDesign aims to install more Simcenter Micred Power Tester solutions to satisfy the demand from their customers who need thermal testing results quickly.

After that, they want to add solutions for analysis and simulation to improve electronic designs after seeing initial test results. Tachibana plans to connect the company’s test systems to Mendix™ software, which is also part of the Siemens Xcelerator business platform, so customers can check their test status and results and download raw data and process it with their own Simcenter Micred analysis software.

“Pairing Mendix with our Simcenter Micred solutions will be more convenient for customers, and it will make a nice add-on to the services business,” says Tachibana.

“I believe that, by evolving the equipment and the jigs, we can continue to provide unique value to our customers. In the longer term, the adaptability of the Simcenter Micred T3STER and Simcenter Micred Power Tester equipment to various manufacturing processes will mean we can broaden the areas where it is used.”

-640x360.jpg?auto=format,compress&w=843&q=60)

Siemens products are the de facto standard in Japan and have tremendous credibility. We have earned our customer’s trust by using this equipment.