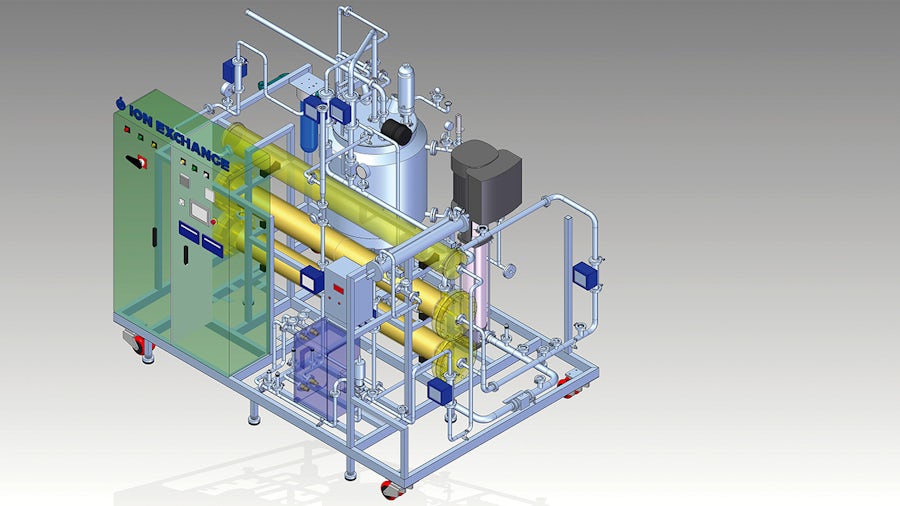

3D CAD helps engineers and customers visualize water treatment products

Using Solid Edge helps Ion Exchange triple design productivity

Ion Exchange

Ion Exchange India pioneered water treatment in India and is the country’s premier company in water and environmental management, with a strong international presence. Formed in 1964 as a subsidiary of the Permutit Company of UK, Ion Exchange became a wholly Indian company in 1985 when Permutit divested its holding. The company currently employs 1,000 people in multidisciplinary teams of highly experienced professional technologists and scientists, supported by a widespread infrastructure in India and around the world. Ion Exchange is celebrating “50 Years of Trust” and stands committed to serve society with total water and environment solutions.

- Centrala:

- Hosur Tamil Nadu and Goa, India

- Produkty:

- Teamcenter Integration for Solid Edge

- Sektor przemysłowy:

- Maszyny przemysłowe

We visited a company that was using Solid Edge to help us understand how it met the organization’s requirements. The company showcased the entire capabilities of Solid Edge, including synchronous technology, and the impact that using the software had on its design team. We also saw how responsive Siemens Digital Industries Software is to its customers.

India’s large market for water purification

From a scientific standpoint, ion exchange is a term used to denote purification, separation, and decontamination processes used to produce clean liquids, such as water. Ion Exchange India Ltd. (Ion Exchange), a water treatment company, delivers solutions for treating household, institutional, commercial, industrial and public water supplies, both urban and rural, in India and around the world.

The Indian water industry is at a crossroads in a developing country with huge requirements for water recycling and purification of drinking water, where there are numerous opportunities for growth. The government sector and private sectors each contribute about 50 percent of the industries’ requirements, while the overall market is growing at a double-digit pace.

Ion Exchange is in a good position to increase its market share because of the company’s depth and breadth of experience. Management ascribes the company’s success to technological advancement through research and development (R&D), noting, “Innovation is our hallmark as our numerous patents testify; affiliations with the best-specialized water treatment companies internationally; human resource development, melding technology with people trained to manage it responsibly; and above all, commitment to customer care that goes far beyond the sale. Technical service support is a key component of our solutions and our service network is the largest in the Indian water treatment industry.”

The role of technology

Ion Exchange engineers had been developing its products using 2D AutoCAD® software, but the 2D computer-aided design (CAD) approach to product development had serious limitations. Errors were common and difficult to find until very late in the product development process. Using 2D AutoCAD did not enable engineers to develop proper documentation and many customers – and even some engineers – were unable to interpret 2D drawings to visualize how real products would look and operate.

“Quick customization was not possible,” says Upendra V. Katti, general manager – operations, Ion Exchange, Hosur. “We used to have lots of revisions in our designs with our 2D CAD application. We had to do two or three manual checks of each product, which led to the creation of huge amounts of data for a single project. We had to work with our production teams to understand how the product would function and look like before we could finalize the design. This led to delays in project delivery times.

“We really couldn’t fully comprehend the design of a product or assembly before it was produced. Standards could not be maintained. So, we started looking for a 3D solution that would help us reduce design time and provide better and more complete visual representations of our products before manufacturing or assembly.”

Ion Exchange was looking for a 3D CAD solution that would help the company reach a number of objectives, including reducing overall design cycle time and cutting back sharply on the number of errors and the time-consuming process of correcting those errors. Additional objectives included producing final products that were 100 percent correct and reducing costs while improving customer satisfaction.

Why Solid Edge with synchronous technology?

Ion Exchange looked at a number of 3D CAD packages, but chose Solid Edge® software from product lifecycle management (PLM) specialist Siemens Digital Industries Software. Katti explains, “Solid Edge has all the features and capabilities organizations like ours need to get the full benefit of using the software. We visited a company that was using Solid Edge to help us understand how it met the organization’s requirements. The company showcased the entire capabilities of Solid Edge, including synchronous technology, and the impact that using the software had on its design team. We also saw how responsive Siemens Digital Industries Software is to its customers.”

Three times faster design

Since installing Solid Edge, Ion Exchange has accomplished all of its objectives. There has been a significant overall reduction in costs due to better design practices. “On average, with the help of Solid Edge, our design cycle has been reduced from 3 weeks to 1 week, so engineers can design products 3 times faster than before,” says Katti.

Time previously spent communicating and clarifying design ideas has been cut by 70 percent. Good documentation can now be easily generated, including 3D drawings with a high level of detail for improved visualization. Today’s designs are also more accurate, enabling Ion Exchange to manufacture parts at multiple locations without any loss in accuracy or productivity. Multiple projects can be managed without having to increase resources because overall productivity has increased substantially.

“Good customer satisfaction and on-time delivery of products has enabled us to capture new business opportunities,” says Katti. “Plus, customers appreciate the value of seeing a virtual 3D representation of the product long before manufacturing is complete.”

On average, with the help of Solid Edge, our design cycle has been reduced from 3 weeks to 1 week, so engineers can design products 3 times faster than before.