Using virtual commissioning to reduce commissioning time by 70 percent

Wipro PARI uses Process Simulate to validate engine assembly line in three months

Wipro PARI

Wipro PARI uses its expertise and resources to deliver automation and robotics solutions to its industrial machinery customers. With a global reach and technical prowess, Wipro PARI offers a comprehensive list of industrial automation solutions, including turnkey physical automation projects and digital factory initiatives.

- 본사:

- Pune, India

- 산업 분야:

- 산업용 기계

With Siemens’ solution, we have significantly improved performance ramp up and mitigated risks.

Reducing manual engineering efforts

Wipro PARI, previously known as Precision Automation and Robotics India Limited, is a leading global developer of automation and robotic systems that was founded in 1990. Headquartered in Pune, India, its customers include established automotive original equipment manufacturers (OEMs) such as Daimler, Mahindra, Ford, FCA, TATA, VinFast, Renault Nissan and The PSA Group. Wipro PARI designs, manufactures and installs complete, automated systems, including multistation lines for machining and powertrain component assemblies.

Today’s rise in digitalization presents an opportunity to bring products to market faster and more efficiently. For Wipro PARI, the virtual commissioning (VC) process was a key element they needed to reduce their manual engineering efforts. The VC process uses simulation technology to create a digital twin of a plant for testing changes before physically implementing them. VC enables manufacturers to perform end-to-end virtual verification, mechanical and control systems design, as well as risk and failure mode and effects analysis (FMEA). This solution ultimately enables engineers to avoid cost-intensive rework.

When a leading automotive OEM approached Wipro PARI to perform VC for a large machining line, the company chose to use Process Simulate in the Tecnomatix® portfolio. Process Simulate is part of the Siemens Xcelerator business platform of software, hardware and services.

Prolonged manufacturing process

Several issues led the OEM to Wipro PARI, including a prolonged manufacturing process due to rework, delayed design validations and unexpected software bugs. Using Process Simulate to create a comprehensive digital twin for performing VC proved to be the ideal solution. Process Simulate is a digital manufacturing solution for process verification in a 3D environment. “By using Process Simulate to create a digital twin, we can validate tomorrow’s machine,” states Latheesh C. Krishnan, corporate head of design validation and virtual commissioning at Wipro PARI.

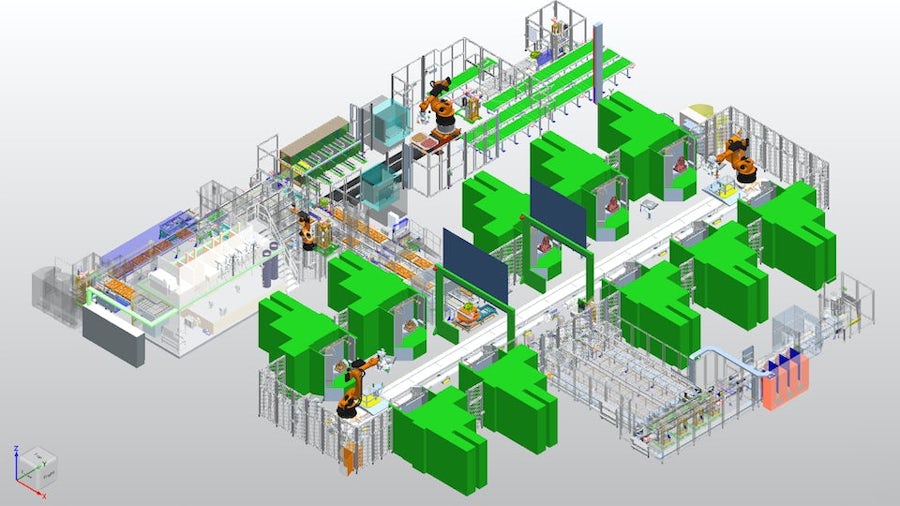

An initial challenge in the project was handling the considerable size of the OEM’s manufacturing process. The machining line consisted of four robots and 10 machining centers: machines for washing, deburring, leak testing and vision checking and over 100 conveyors, slides, positioners, lifters and part variants. Additionally, the line complexity was compounded by its ability to run 17 variants in a mixed-batch mode.

To approach this scale of a VC project, the company divided the assembly line into four zones, each running on a different mode in Process Simulate and Siemens’ SIMIT software. Wipro PARI used hardware-in-the-loop (HiL) configuration for programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to test several types of safety interlocks. Further, they performed offline programming (OLP) integration for robots and customized extensible markup language (XML) to enhance the functionality to match their needs from the OLP. Then they simulated radio-frequency identification (RFID), vision system interfaces, scanners and safety logic written in safe central processing units (CPUs).

Wipro PARI received a high degree of technical support from Siemens’ engineers during critical stages of the project. The company appreciates Siemens’ efforts to respond to customer feedback. The reporting mechanism developed through Siemens’ GTAC site enabled Wipro PARI to address their technical challenges. Siemens’ development team in Israel responded positively and the results were visible in further version releases of Process Simulate.

Virtual commissioning reduces rework and delivery time

By incorporating VC with HiL, Wipro PARI minimized rework by 40 to 50 percent and reduced delivery time by 5 to 10 percent. “Virtual commissioning enables us to validate and optimize equipment performance for all complex use cases and failure modes early in the project lifecycle,” claims Dr. Ranjit Date, chief executive officer (CEO) of Wipro PARI.

Parallelly, Wipro PARI completed another VC project of a production volume up on a brown field engine assembly line in three months from design to shop floor commissioning. This could have been a six to eight-month job in normal conditions. In addition to improving process reliability and resolving design and process issues early on, they reduced on-site commissioning time by 70 percent. “With Siemens’ solution, we have significantly improved performance ramp up and mitigated risks,” states Date. They also improved collaboration between design and manufacturing by removing barriers between mechanical, electrical and control engineers.

Once these projects were completed, the team realized the value and growth that Process Simulate provided and decided to develop a VC department in-house. “Now we can help our customers with error-free PLC, CNC, robot programs and process optimization without prototyping or production blockage and expansion experiments and more,” says Krishnan.

Expanding virtual commissioning department

The team can now simulate end-to-end line architecture (on the mechanical and automation side) irrespective of the controller whether it is PLC-based or computer numerical control (CNC) based. Wipro PARI has now been approached by multiple customers to create similar VC solutions. Wipro PARI’s future plans are to expand from line-level VC to plant-level VC, support Industry 4.0 with smart factory developments by using the digital twin, perform software testing only using the digital twin and provide VC as a service for the manufacturing industry.

Now we can help our customers with error-free PLC, CNC, robot programs and process optimization without prototyping or production blockage and expansion experiments and more.