Industrial automation company uses Process Simulate to reduce project time by 30 percent

Using Siemens Digital Industries Software’s Tecnomatix portfolio enables SGAR to enhance productivity, profitability and competitiveness

SGAR

SGAR is a Spanish company that specializes in engineering and industrial automation. Founded in 2001, the company offers programming, validation, and implementation of production line services.

- 본사:

- Barcelona, Spain

- 산업 분야:

- 자동차 및 운송

With Process Simulate, it takes us approximately 30 percent less time to carry out a project, and we are able to do work that we could not do before.

Ensuring the success of large projects

SGAR is a Spanish engineering and industrial automation company that specializes in software design, programmable logic controllers (PLCs), robot programming (palletizing, welding, loading/unloading, etc.) and hardware engineering (electrical installations, hardware implementations, etc.) The company mainly provides programming, validation and implementation of production-line services. Founded in 2001, company headquarters is located in Barcelona, with facilities in Vitoria-Gasteiz and Zaragoza.

The team consists of 50 engineers and automation professionals, and executes around 120 projects per year. Most projects are for automotive companies (Mercedes Benz, Opel, Nissan, SEAT, Volkswagen, etc.), but also include clients from other industries such as food and beverage (Heineken, San Miguel, Damm, Puleva), water treatment (ATLL) and large infrastructure (notably luggage management at Barcelona’s El Prat airport and various services for the electrical installations of the south terminal).

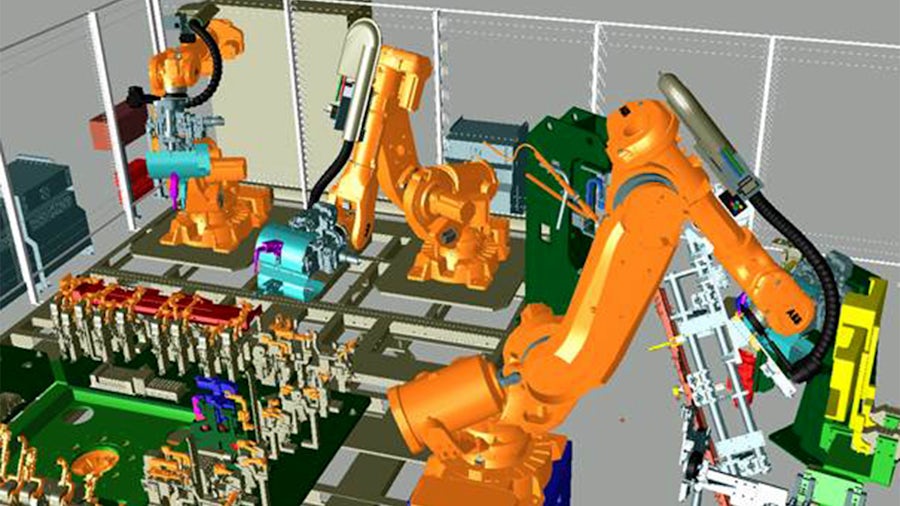

Today’s market calls for highly automated and flexible manufacturing systems that include sophisticated tools, robots, transfer lines and safety equipment, with everything controlled by PLCs. Once the mechanical supplier has provided the documentation with the characteristics and requirements of the installation, SGAR is the electrical provider that determines the appropriate kinematics of the processes and components by using accessibility studies, and also generates program codes for the controllers of various robots.

The work that SGAR carries out is essential to advancing the success of large projects that demand high quality. The company works in environments where they must integrate equipment in a predetermined physical space, and all elements must operate properly, avoiding collisions and errors that could result in significant financial losses.

Market demands

SGAR faces two challenges in accessing new business. First, it has to be able to work in all kinds of facilities regardless of the systems and robot models required by the customer. Second, it must deliver results with maximum precision and quality, reducing time and cost in order to increase profitability.

Continuing to perform onsite work – going to the client’s facilities and taking references manually – involves a large time investment and complicated paper and digital documentation that make collaborative work impossible.

“Our commitment is to be more competitive, provide high-quality services, work with PLM products and introduce ourselves to the world of virtual manufacturing,” says Frederic Cubells, director of robotic simulation at SGAR. For that reason, five years ago, the company introduced product lifecycle management (PLM) specialist Siemens Digital Industries Software’s Robcad™ software in the Tecnomatix® portfolio as a 3D tool for the simulation, optimization, validation and scheduling of processes for robotic and automated manufacturing. They did so under the guidance of T-Systems, a Siemens Digital Industries Software partner and specialist in solutions for the lifecycle of products in the automation, aerospace, production and discrete manufacturing sectors.

In addition to meeting the needs of many of SGAR’s customers, it was the tool’s advanced capacities and the strength of the Siemens Digital Industries Software brand that were the determining factors in choosing this solution.

“The majority of our work is turnkey,” says Cubells. “Our clients indicate the working method and deliver documentation, and many of them require that we have this tool. It has been strongly positioned in the automotive industry for many years, and having it was fundamental. It fit into our business model perfectly, and resolved any shortcomings that we had.”

SGAR was so satisfied with Robcad that, when Siemens Digital Industries Software launched the Process Simulate solution in the Tecnomatix portfolio as part of its internal evolution, it did not hesitate to invest in this innovative tool. The company immediately incorporated this new solution into its processes, counting on the proactive advice and constant support of T-System to adapt the program to its business needs.

“Because of our participation in many European projects, we began to notice a clear tendency in the sector to migrate to Process Simulate, so we decided to do the same,” says Cubells. “Currently, we alternate between both tools, but we prioritize the use of the software, with Process Simulate first in line.”

Advanced PLC programming

The use of Robcad and Process Simulate provide SGAR with a virtual environment, advanced tools to validate the data provided by the mechanical supplier and the ability to completely simulate manufacturing environments. “Since we previously did not have products to evaluate the mechanical field, we couldn’t offer our experience, correct errors or propose possible improvements that are usually detected during the initial phase when we receive the project,” explains Cubells.

Process Simulate has two modules that have been critical for optimizing SGAR’s work: robotics and virtual commissioning. Robotics is the solution that allows for offline programming (OLP) of robots and, at the same time, includes two utilities with innovative technology that allow for project optimization: the Weld distribution center and Cyclic event evaluation (CEE).

“The Weld distribution center is an organizational tool that allows us to automatically move welds from one station to another, thus avoiding duplication errors that might arise during manual changes,” notes Cubells. ”It is extremely practical because it makes the work easier and it allows us to quickly evaluate the work balance between robots. And, with CEE, we can perform much more realistic line simulations, filling them with parts and generating 3D videos. Thanks to this, we are able to detect bottlenecks in the process at the very beginning of the project and with greater security.”

Virtual commissioning allows for the debugging of PLC code in a virtual environment before downloading it onto the actual equipment. “The simulation and validation of automation equipment allows us to confirm that they are going to work in a certain way and as expected,” says Cubells. “It also significantly reduces the system boot time.”

Tools that improve productivity

The transition from Robcad to Process Simulate is allowing SGAR to check improvements introduced by Siemens Digital Industries Software in a product that has led the market in industrial virtualization for many years. This was the case with the Process Simulate Spot (Spot) module that enables the validation of weld points. In the past, it took the company a considerable amount of time to perform the functions step-by-step and then wait for the test, but it was able to complete the work quite easily with excellent results. “Now, for example, because of the advanced capabilities of Process Simulate and the use of a more modern architecture, we can mark one piece and set the equipment to weld 100 points all at once,” explains Cubells. “A task that used to take half a day to execute is now performed in approximately 30 minutes.”

Cubells also highlights changes in arc welding: “With Robcad, we had to make several attempts to guide a weld in 3D. Now, the tool is much more stable, and you can practically succeed on the first attempt.”

He also mentions his satisfaction with the greater agility and execution speed in the anti-collision model (dynamic and static), as well as improvements when performing 3D measurements: “They are more accurate and the environment is much more intuitive,” says Cubells. “It resembles a CAD (computer-aided design) tool. It saves a lot of time and you can provide the client with much more detail when informing them about completed work.”

Cubells has high regard for the new possibilities of generating and managing documentation for clients throughout the lifecycle of a project: “Process Simulate allows us to deliver all kinds of details in a very simple manner: if we’ve found errors in the mechanical assessment, aspects that are not validated, comments, etc. It allows for the maximum communication of this information. It has tools to create ad hoc snapshots and 2D and 3D videos with all kinds of editing support, such as inserting text, arrows and circles to draw attention to certain areas. Now, we don’t waste time creating presentations and other documents.”

The commitment to innovation that SGAR has made by incorporating Process Simulate has allowed the company to provide more competitive services, especially in its basic business environment. The automated body-in-white (BIW) processes in the automobile sector were covered by Robcad until now. Specifically, the robotic simulation team took part in defining mechanical layout and validation, relying mainly on the Spot and Process Simulate Continuous Manufacturing (Continuous) modules and offline/cycle time programming. The team also combined the capabilities of robotics with its own robot systems (offline programming and robot containerization systems) to enable integration and virtual implementation, in which robotics and virtual commissioning are essential.

Greater agility and flexibility

With Robcad, SGAR propelled its business forward by using virtual simulation in manufacturing environments as a way to set themselves apart from its competitors. The use of Process Simulate has placed the company at the forefront of the sector thanks to its agility and speed, providing new capabilities and improvements. It is these characteristics that allow the robotic simulation team, made up of just six people, to take on difficult projects.

A fundamental difference between the two programs is the operating platform: Robcad runs on UNIX® system, and Process Simulate runs on the Windows® operating system. “This means that we work in a completely familiar and intuitive collaborative environment, and that we can interact with higher-level tools such as Process Designer to obtain information from our providers quickly and easily,” says Cubells.

“With Process Simulate, it takes us approximately 30 percent less time to carry out a project, and we are able to do work that we could not do before,” says Cubells. “Now, we have the know-how that sets us apart in the market and places us at the forefront of our sector. The advanced features and simulation capabilities of Process Simulate allow us to anticipate changes that need to be made before anything goes to the production line. This directly affects our costs and the client’s final costs, and results in customer satisfaction and loyalty.”

The advanced features and simulation capabilities of Process Simulate allow us to anticipate changes that need to be made before anything goes to the production line.