Heat pump manufacturer uses Simcenter STAR-CCM+ to rapidly explore design space and bring products to market faster

Siemens Digital Industries Software solutions enable Sanden to lower development costs and maximize product performance

SANDEN

Sanden develops unique CO2 technology for a large range of heating and cooling applications, including heat pump water heaters, space heating heat pumps, air conditioners, commercial refrigeration systems and vending machines. In collaboration with their global headquarters in Japan, Sanden manufactures its own key components, with a focus on energy conservation and efficiency.

- 본사:

- Tinténiac, Brittany, France

- 제품:

- Simcenter STAR-CCM+ Essentials

- 산업 분야:

- 자동차 및 운송

The automated and integrated design exploration approach with Simcenter STAR-CCM+ saved us a significant amount of time and expense. Without it, we could not have achieved this level of performance improvements.

Old challenges, new solution

Gaining market share in an established, competitive market – like the one for domestic hot water heaters – is always a challenge, even when you’re introducing customers to higher-performing, environmentally-friendly product options. This challenge further amplifies the need to reduce the time and costs involved in the design and development of new products. In cooperation with advanced development engineers, the thermal engineers at SANDEN Manufacturing Europe (SME) met this challenge by relying on computational fluid dynamics (CFD) simulations to design a key component of an innovative heat pump that uses carbon dioxide (R744) as the working fluid. They used Simcenter™ STAR-CCM+™ software from Siemens Digital Industries software to perform the simulations, resulting in savings of €31,000 and 36 weeks – the cost and time required to build and test two physical prototypes, which were rendered unnecessary by the simulations. Additionally, the SANDEN engineers performed fully automated CFD-based design explorations – using Design Manager, a multidisciplinary design exploration tool that is part of Simcenter STAR-CCM+ – to determine the optimum shape of the passageways that direct air through the heat pump’s evaporator to maximize the heat transfer that occurs in the evaporator. Running Design Manager for six days on 24 CPU cores, the SANDEN engineers explored a much broader range of design possibilities, resulting in a configuration that was not only delivered in less time and cost, but which also significantly outperformed previous designs developed using conventional, manual approaches (including a 60 percent improvement in the air recirculation ratio – a key performance metric in determining the heat transfer occurring in the evaporator).

Adrien Rochelle, an advanced development engineer at SME, summarized their experience: “The automated and integrated design exploration approach with Simcenter STAR-CCM+ saved us a significant amount of time and expense. Without it, we could not have achieved this level of performance improvements.”

Simulation – the key to reducing development time and cost

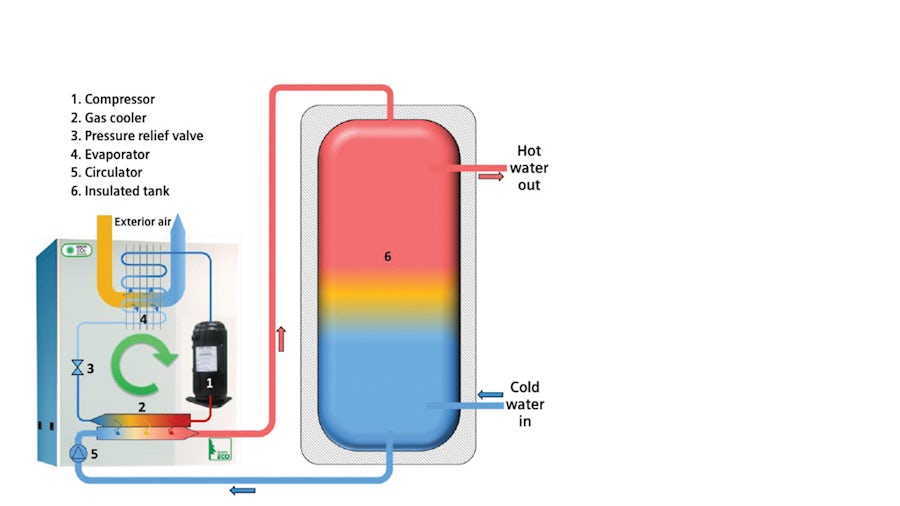

SANDEN Japan pioneered the development of heat pumps for residential sanitary water heating, using CO2 as the refrigerant fluid, in response to the ever-present demand for better performance and greater energy efficiency. These CO2-based heat pumps have emerged as an attractive option due to their superior performance and energy efficiency compared to traditional electric water heaters. Additionally, CO2 is an eco-friendly, natural refrigerant – compared to the fluorinated gases (F-gases) more commonly used in heat pumps, CO2 has no ozone depleting potential (ODP), has very low global warming potential (GWP), and is non-flammable and non-toxic. Consequently, CO2-based heat pumps are an ideal match for use in the new wave of buildings being designed with low energy consumption in mind, as they comply with the latest regulatory requirements for high energy efficiency and use of renewables.

An integrated pump draws cold water from the bottom of the water tank; the heating of the water occurs as it flows through the gas cooler, which is a heat exchanger (coaxial countercurrent type). This results in an increase in the water temperature, from 10°C to approximately 65°C, after which the hot water is then directed to the top of the tank, near the hot water outlet, allowing an almost immediate availability of water at 65°C.

As a relatively new technology, the cost of parts for these CO2-based systems is high compared to those in traditional (hydrofluorocarbon) electric heat pumps. As such, the need to minimize the time and costs required to take the technology to market is particularly acute. One way to meet this challenge is minimizing the reliance on physical prototypes in the development process, as they are very expensive (in addition to being slow to build and test). At SANDEN, this meant using Simcenter STAR-CCM+ to automate the search for the best design for a critical component of the system – the evaporator.

The evaporator is a heat exchanger in which exterior air flows over refrigerant-filled passages, resulting in the refrigerant (CO2) absorbing heat from the exterior air. Better heat transfer in the evaporator results in better performance of the entire system. As such, it is critical to shaping the passageways that direct air through the evaporator in such a way as to maximize the heat transfer that occurs in the evaporator.

Figure 2-2: Detail of ducting geometry surrounding the evaporator. Corresponding computational mesh is highlighted in purple.

Figure 2-1: Detail of ducting geometry surrounding the evaporator and its corresponding computational mesh. Evaporator is marked as component 4.

Design exploration, not just assessment of individual designs

Based on their years of experience in the design of evaporators used in these heat pumps, the thermal and advanced development engineers at SANDEN had established three well-defined criteria that must be satisfied to maximize the heat transfer in the evaporator:

- The air velocity on the evaporator interface should be as uniform as possible; specifically, the standard deviation of the velocity magnitude should be less than 0.28 m/s.

- The velocity of the air flowing through the evaporator should not exceed 1.8 m/s.

- The air recirculation ratio should be less than five percent. The recirculation ratio is defined as the percentage of a cross section through which the air flows in the opposite direction after passing through the evaporator; this is to be minimized as it negatively affects the efficiency of the evaporator.

The geometry of the ducting surrounding the evaporator is illustrated in figure 2-1, along with the computational mesh used in the Simcenter STAR-CCM+ simulations in figure 2-2. A centrifugal fan (component 6 in figure 2-1) draws exterior air through the upstream duct (1), past the top suction section (2), into the suction chamber (3), and through the evaporator (4). The air is then drawn into the shroud (5), then into the fan casing (7) before finally being sent out by the fan (6) to the downstream duct (8). The twisting path the air takes attests to the magnitude of the design challenge, which is magnified by the fact that the evaporator around which the duct is being designed is quite small.

The SANDEN engineers were already aware of the value of virtual prototypes and simulation – they had been running Simcenter STAR-CCM+ simulations of the flow through the evaporator for validating design variants that they had developed based on their own expertise. These were validation runs carried out to understand the effects of individual design parameters, not necessarily to drive the identification of new candidate designs. Even so, these runs had already resulted in the identification of a good “baseline” design that met the maximum velocity criteria listed above (but not the other two).

The challenge for the SANDEN engineers, then, was to speed up the discovery of duct shapes that met all their performance criteria. Their initial approach was to automate the traditional design of experiments (DOE) plan they would have performed manually in past years to determine the effects of changing a small number of design variables. Using a Java macro, they developed a procedure to automate the evaluation of design points but found that it was slow and cumbersome, even when considering as few as five design parameters. They then turned to Design Manager – the design exploration tool within Simcenter STAR-CCM+, which is purpose-built for conducting automated exploration of the design space--to guide their design process.

As illustrated in figure 3, design exploration with Simcenter STAR-CCM+ represents a fundamentally new way of conducting engineering design. The traditional approach (such as the DOE plan mentioned earlier) involves simply simulating the CAD model, assessing whether the performance of a particular design is “good enough,” then performing successive simulations on variants of that design until performance criteria are met. This was a perfectly reasonable approach back when computing resources were limited, but it suffers from a number of significant drawbacks, including limited model fidelity and the inability to handle large numbers of design parameters. True design exploration starts by defining the performance criteria (the objectives) upfront and then using intelligent search algorithms (or better yet, multiple algorithms) to discover families of better designs. This allows for using computational models of high fidelity (to capture the pertinent physics), parameterized using a large number of design variables.

In the case of the ducting for the SANDEN evaporator, the engineers used 12 design parameters in their Design Manager study, as shown in figure 4.

Figure 4: The 12 design parameters used in the Simcenter STAR-CCM+ Design Manager study.

Figure 3: Traditional design approach versus design exploration.

Seemingly small changes result in big performance gains

Figure 5 shows a comparison of the “baseline” duct design and the design found after running Design Manager for six days on 24 CPU cores. While the geometrical differences may not be readily apparent from a casual visual comparison of the two configurations, looking at the changes in the numerical values of each of the 12 design parameters reveal that several of the values changed significantly.

More importantly, the effects of the changes on the performance metrics are significant, as shown in figure 7.

Figure 7 highlights an important benefit of the kind of design exploration that Design Manager allows one to conduct: the exploration leads to families of better designs, which allows designers to choose the design whose performance represents the best balance – in the case of the evaporator ducting, the final design that the engineers at SANDEN selected was the one that had the lowest recirculation ratio, even though it had higher values of maximum velocity and velocity standard deviation than the representative design indicated by the red columns. In addition, Design Manager allows you to gain an understanding of which design variables have the greatest effect on specific performance objectives (no small feat when you have several design variables, as in this case).

It should be noted that the design exploration conducted by the SANDEN engineers involved a total of 59 Simcenter STAR-CCM+ evaluation runs. These resulted in 39 designs which satisfied all three performance criteria, 19 that did not meet at least one of the three criteria, and only one that resulted in a code error. The low error rate was the result of close collaboration between the SANDEN engineers and their dedicated Siemens support engineer to develop a process for carefully specifying minimum and maximum tolerances on each of the design parameters in order to reduce the occurrence of geometrically impossible situations.

The increased uniformity of the flow velocity at the evaporator interface in the improved design is evident in figure 8, which shows the velocity variation at that interface. In addition, the areas of recirculation (indicated by the white areas in the velocity distributions) have been virtually eliminated.

Figure 7: Performance comparison of baseline and Design Manager improved designs, in addition to selected “final” design.

Figure 5: Comparison of baseline design and result of Design Manager exploration study.

Conclusion

The use of Simcenter STAR-CCM+ at SME’s Technical Centre of France resulted in significant cost and time savings. Simcenter STAR-CCM+ simulations gave them the confidence to forego the (slow and expensive) building and experimental testing of two prototypes, and Design Manager found significantly better performing designs in a fraction of the time that it would have taken to build and test the prototypes.

Beyond the time and cost savings, there are the gains made in the fundamental understanding of the effects of each design parameter on the system’s performance. Adrien Rochelle sums it up this way: “For me, with the design exploration capabilities of Simcenter STAR-CCM+, we’ve increased our understanding of the performance and the design of our fluid vein design. We now know the effects of the design parameters on the main responses and it represents a fundamental improvement in our understanding. The simulation provides us with a kind of insurance in our design development by providing new knowledge and mastery of our design.”

What’s next for the team at SANDEN? Adrien says, “We are now developing the same process for automotive air conditioning compressors in Sanden Manufacturing Europe.”

Figure 8: Comparison of velocity distribution at the evaporator interface.

For me, with the design exploration capabilities of Simcenter STAR-CCM+, we’ve increased our understanding of the performance and the design of our fluid vein design. We now know the effects of the design parameters on the main responses and it represents a fundamental improvement in our understanding. The simulation provides us a kind of insurance in our design development by providing new knowledge and mastery of our design.