Using NX Virtual Machine Tool enables automotive parts manufacturer to reduce setup time by 20 percent

Grieshaber Group fully leverages INDEX machines by implementing Siemens Digital Industries Software solution

Grieshaber

Grieshaber machines and produces over 120 million precision parts from non- ferrous metals annually, primarily for the automotive industry. It is part of a corporate group that also includes VEGA, which manufactures level and pressure measurement equipment, and Subfina, which produces surface finishing systems.

http://www.grieshaber-praezision.de

- 본사:

- Schiltach, Germany

- 제품:

- Assembly Line Planner X

- 산업 분야:

- 자동차 및 운송

I can see if a certain position is too long as early as in the planning stages. So I can achieve my planned cycle times on the real machine much faster.

Optimizing CNC code

More aluminum rods are machined in the small German town of Schiltach at the Grieshaber GmbH & Co. KG (Grieshaber) plant than at any other location in Germany. Grieshaber annually processes up to 3,500 tons of aluminum into high- precision parts for the automotive industry, many of which are safety-critical components. “We supply many first-tier suppliers with hard-to-manufacture parts,” says Günter Weißer, the production manager at Grieshaber.

Machining aluminum into high-quality parts is one of the Grieshaber’s core competencies; in the latest supplier survey, Grieshaber achieved an impressive reject rate of just 0.8 parts per million (PPM). The company also manufactures high-precision stainless steel parts used in special applications in measuring and sensor equipment, machine and apparatus engineering, and medical equipment. Grieshaber’s biggest customer for high-precision stainless steel parts is its affiliate VEGA, which manufactures measuring and level sensor equipment, and exports this equipment across the globe.

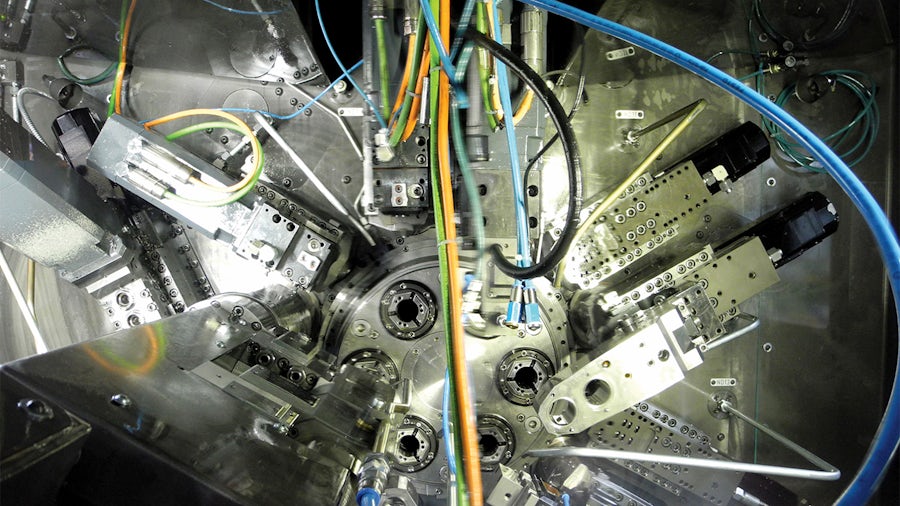

Although the machining of stainless steel parts is predominantly carried out on single-spindle machines due to the lower piece count, the aluminum parts are usually machined on multi-spindle turning centers. Grieshaber relies on products from INDEX and product lifecycle management (PLM) specialist Siemens Digital Industries Software for a winning combination. The fleet of machines encompasses nearly 20 six-spindle machines, including INDEX MS 22, MS 32, MS 40, MS 50 and MS 52 in a variety of configurations. They are equipped with Siemens’ SINUMERIK 840D controls. Grieshaber’s most recent acquisition is the INDEX MS 22-8, which has eight spindles and can cut parts with higher complexity, or parts with less com- plexity at a faster rate.

In the past, a 2D computer-aided manufacturing (CAM) system that only offered minimal options to monitor and detect collisions was routinely used to program single- and multi-spindle machines. The operators would only see what they programmed once the computer numerical control (CNC) program was executed.

“We used to have to play around with the CNC code and weren’t able to import the adjustments that we made back into the CAM program,” says Thomas Dieterle, Technical Planning, Grieshaber. “Now I can prepare the program using the Virtual Machine Tool, send it to the real machine, check the quality and then import it back into the Virtual Machine Tool to further optimize the CNC code.”

The distribution of operations of the virtual machine are discussed. Illustration: Wendenburg.

The fleet of machines includes over a dozen multi-spindle machines from INDEX, which are all equipped with SINUMERIK 840D control. Illustration: Wendenburg.

Cutting cycle times

The Virtual Machine Tool 840D in the NX™ software suite of solutions from Siemens Digital Industries Software is a CNC programming and simulation environment that allows the user to program the machining operations on a standard personal computer (PC), just as the user would on the real machine. The difference is that using the Virtual Machine Tool, an operator or setter can see if the machine will do what the operator thought it would do in a simulation on the computer. Unlike ordinary CAM programs, the Virtual Machine Tool doesn’t just enable the user to visualize the machining process and toolpaths, it simulates the machine movements based on the generated CNC code. Virtual Machine Tool solutions are configured by machine tool original equipment manufacturers (OEMs), such as INDEX, using a flexible software kit available from Siemens Digital Industries Software. The Virtual Machine Tool is built on real SINUMERIK controller software (not a software emulator like most machine tool simulations) and the human machine interface (HMI), combined with full-function machine simulation system, and is calibrated using configuration data from the SINUMERIK controller on the real machine tool. This provides the most complete simulation, and means that using the Virtual Machine Tool is just like working on the real machine.

“The machining operations are not only displayed from a kinematic standpoint to detect any possible collisions, but they’re also simulated according to their proper temporal sequence and duration,” says Hubert Firner, Technical Planning, Grieshaber. “With the help of a simple image, the user can see how long the tools are in operation on each spindle, and make any necessary changes to distribute the operations more evenly.”

“I can see if a certain position is too long as early as in the planning stages,” says Dieterle. “So I can achieve my planned cycle times on the real machine much faster.”

To optimize cycle times and reduce the time that INDEX machines stand idle (for example, by shortening a feed path and thereby cutting off a tenth of a second from the cycle time), the Virtual Machine Tool provides the same ability to record cycle times that is also available on the real machine. A tenth of a second can quickly add up to a savings of several days per year when dealing with hundreds of millions of parts. That’s why such optimizations were also performed in the past, albeit irregularly, since it always required a stoppage of the machines. It only made sense for parts that were machined in large quantities.

These stainless-steel pressure connectors used in measuring and sensor equipment were machined with the multi-spindle INDEX MS 40. Illustration: Grieshaber.

The mobile workstation allows adjustments to the multi-spindle machining process in advance on the virtual machine. Illustration: Wendenburg.

Reducing setup time by 20 percent

The effect of the Virtual Machine Tool on machine operating times is not yet fully known. However, as Weißer says, “The changeover time for preparing new parts has decreased by approximately 20 percent.”

“The time saved depends on the complexity of the part and on any additional equipment that has to be mounted,” says Firner. “Thanks to its easy-to-use design, the Virtual Machine Tool is already very useful in the ordering stage, since it lets you calculate operation times reliably which, in turn, allows you to provide a very precise quote to the customer.”

The savings potential of running a CNC program is amplified, since it’s also a question of how much a machine setter can trust the program. Even more important is that the Virtual Machine Tool is an open network solution with multiple user licenses. The machine setter has a stationary and mobile workstation, so the setter can view the processing of a new part on the computer, but also optimize an exist- ing CNC program even further. That makes the Virtual Machine Tool the setter’s tool as well. The machine setter and machine operator receive training on the Virtual Machine Tool without having to shut down the real machines. As a result, Grieshaber can train and familiarize more employees with both the machines and their controls.

The Virtual Machine Tool allows a user to virtually simulate and optimize mechanization on the INDEX machines, shortening idle times for changeover. Illustration: Grieshaber.

The changeover time for preparing new parts has decreased by approximately 20 percent.