Use of Simcenter enables manufacturer to significantly reduce compressor testing time

GEA Grasso cuts number of testing systems from 3 to 1 with the help of Siemens Digital Industries Software solutions

GEA Grasso

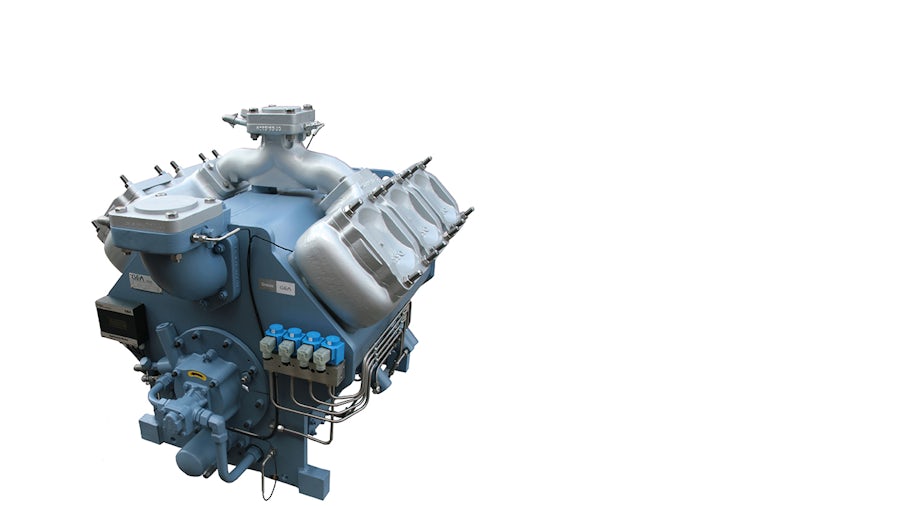

GEA Grasso has been manufacturing compressors for industrial refrigeration for more than a century. The company designs, engineers, installs refrigeration compressors and compressor systems based on quality, reliability and total cost of ownership. Its customers rely on industrial refrigeration as an essential part of their primary process.

- 본사:

- ’s-Hertogenbosch, Netherlands

- 제품:

- Simcenter SCADAS Mobile hardware, Simcenter Testxpress software

- 산업 분야:

- 산업용 기계

Thanks to Simcenter Testxpress, we were able to increase our testing efficiency and managed to reach an important NVH signoff point in less than 50 percent of the time it would have taken before

Reducing heat

Modern refrigeration processes comprise a wide variety of highly advanced techniques to remove heat from an enclosed space. These methods range from vapor compression and vapor absorption refrigeration to thermoelectric and magnetic refrigeration. Vapor-compression cyclical refrigeration is the most widespread form of refrigeration for household and commercial refrigerators, air-conditioning installations, the food processing industry, refrigerated trucks and other large industrial refrigeration systems. With this particular refrigeration technique, the liquid refrigerant evaporates by absorbing the heat contained in the space to be cooled down, thereby lowering its temperature. Later in the circuit, the gaseous refrigerant is compressed and condensed again into a liquid state, releasing the heat.

Finding the source

The vapor-compression refrigeration system consists of four main components: a compressor, a condenser, an expansion valve and an evaporator. Different compressor types can be used in refrigeration systems depending on the particular application as well as the size, noise, efficiency and pressure issues. The most commonly used refrigeration compressors are reciprocating and rotary screw compressors. As with any mechanical device, compressors are subjected to noise and vibration issues that might compromise the manufacturer’s quality standards and customer satisfaction.

When vibro-acoustic problems occur, it is crucial to determine the acoustic hotspots and detect structural resonances. Extensive experimental testing with dedicated measurement systems can be used to help uncover where these issues originate, and provide valuable information on how to optimize the design to prevent these issues from resurfacing.

Improving testing

When GEA Grasso, a Dutch component manufacturer for industrial refrigeration installations, considered improving its testing systems for compressor measurements, it turned to Siemens Digital Industries Software for help in developing a more integrated and flexible data acquisition and analyzer system. GEA Grasso has more than a century of experience in producing compressors for industrial refrigeration and it is one of the leading manufacturers of innovative reciprocating compressors and packages.

“When developing compressors, we have to take into account important design criteria, such as reliability, durability, energy efficiency, maintenance and depreciation costs, flexibility in capacity control as well as noise and vibration,” says Hans Vermeer, manager of the testing department at GEA Grasso. “Vibrations will become increasingly important in the future due to new building designs. For instance, buildings with flexible steel construction or machine rooms that are situated above an office can easily radiate noise, so keeping compressor vibrations to a minimum is crucial for us.”

The refrigeration compressors that GEA Grasso produces are low-speed piston compressors that work at 500 to 1500 revolutions per minute (rpm) with a relatively large piston that generates relatively high compression forces between 8 to 50 hertz (Hz). At these low frequencies, building foundations and steel construction parts as well as piping and other large components are easily disturbed and might cause problems ranging from simple annoyance to severe situations, such as tearing piping welds and causing refrigerant to leak.

Seeking a user-friendly and efficient system

To deal with compressor vibration issues, GEA Grasso used to rely on three different measurement systems: one system to carry out sound intensity measurements, identify acoustic hotspots and sound power levels; a second system to perform impact testing and discover structural resonances and a third to perform valve positioning measurements for compressors that need charge conditioning. Since these systems were becoming outdated and required increasing and separate maintenance costs, GEA Grasso was looking for a more user-friendly and efficient measurement system to handle all its compressor noise and vibration testing.

GEA Grasso was able to meet its specific needs by implementing Simcenter Testxpress software and Simcenter SCADAS™ Mobile hardware from Siemens Digital Industries Software. Simcenter Testxpress combines the ease of use of a traditional analyzer with the high-speed performance and measurement quality of an advanced noise and vibration measurement system. It is seamlessly integrated with the Simcenter SCADAS Mobile data acquisition front-end.

The compactness, flexibility and integrated data acquisition and analysis capabilities of Simcenter Testxpress helped GEA Grasso reduce the number of its testing systems from three to one. Not only did this greatly improve efficiency, but it also drastically decreased testing time.

“Thanks to Simcenter Testxpress, we were able to increase our testing efficiency and managed to reach an important NVH signoff point in less than 50 percent of the time it would have taken before,” says Vermeer.

Vibrations will become increasingly important in the future due to new building designs. For instance, buildings with flexible steel construction or machine rooms that are situated above an office can easily radiate noise, so keeping compressor vibrations to a minimum is crucial for us.