Automotive and construction machinery manufacturer uses Teamcenter product costing to realize value costing accuracy greater than 95 percent

Siemens Digital Industries Software solution enables Weichai Power to enhance competitiveness and maintain sustainable development

Weichai Power

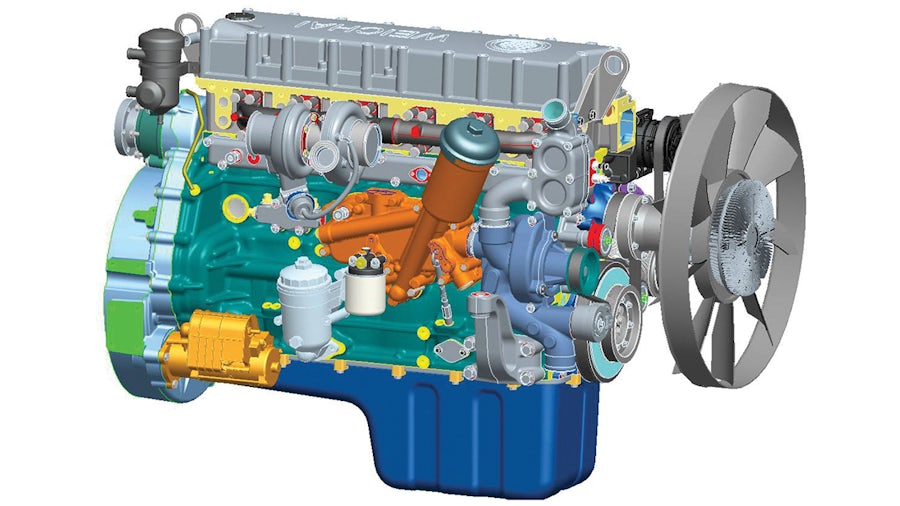

Weichai Power is committed to creating products that are competitive in terms of cost, technology and quality, and develops solutions for four key sectors: powertrain (engines, transmissions and axles), vehicles and engines, hydraulic control and auto parts. It has become one of the top players in China’s automotive and equipment manufacturing industries.

- Sede centrale:

- Shandong, China

- Settore industriale:

- Industria automobilistica e dei trasporti

By using Teamcenter we have solved the product inconsistency problem, maintained product quality (precision) and significantly improved working efficiency.

Becoming a top player

Weichai Power Co., Ltd. (Weichai Power) was founded in 2002, and is part of the Weichai Holding Group Co., Ltd. The company is committed to creating products that can compete on the basis of cost, technology and quality. Weichai Power built a new layout for the development of products for four key sectors: powertrain (engines, transmissions and axles), vehicles and engines, hydraulic control and auto parts. Having formed the most complete and competitive industry supply chain in China’s automobile industry while boasting technologies and products that are critical to the construction machinery industry, the company has become one of the top players in the country’s automotive and equipment manufacturing industries.

With engines and vehicles as its leading products and the powertrain system at its core, the company’s vision is to become a world-leading, sustainable industrial equipment manufacturing group that possesses core technologies. For years, Weichai Power has optimized all business processes affecting the operating efficiency based on product lifecycle Automotive and transportation Weichai Power Automotive and construction machinery manufacturer uses Teamcenter product costing to realize value costing accuracy greater than 95 percent management (PLM), enabling them to maintain sustainable development.

Enhanced cost competitiveness

Liu Xingyin, director of the Department of Value Engineering, explained that Weichai Power set up the department in March 2012 in response to the call from Tan Xuguang, chairman of Weichai Power, to create competitive products in terms of cost, technology and quality, and especially enhance overall corporate cost competitiveness.

“The Department of Value Engineering is very important,” says Liu Xingyin. “Our mission is to create the optimal value chain for Weichai Power. Our tasks are all about product value, about how to enhance productivity and reduce costs, and how to incorporate it into all processes, including product design, materials purchasing and production.”

Weichai Power has achieved value control over the entire product lifecycle. Engineers introduce the concept of value at the beginning of product design, figuring out the optimal cost that maximizes customer value. They then set a target cost based on market rules and historical data, implementing the target cost at all design stages, including conceptual, layout and detailed design. Finally, they monitor the product cost throughout the product lifecycle process, thus realizing product value management.

In the case of cost analysis for an individual product, Weichai Power has broken away from traditional practices such as qualitative analysis and price comparison purchasing. Instead, by using PLM specialist Siemens Digital Industries Software’s Teamcenter® solution for product costing, the company can now accurately itemize and measure all cost factors according to the product development process, theoretically enabling them to identify the precise cost of a product and make it a benchmark for purchase price and sale price calculations.

Over the years Weichai Power has accumulated a wealth of cost data, and established a database and value model to calculate the costs of diesel engine components. The database is used to determine the standard process, cutting allowance, man-hour rate, unit price of equipment and period expense, etc. Theoretically, the exact value of a product component can then be calculated based on the database and entire cost management process.

“However, as the product lifecycle got shorter while the product structure became increasingly complicated, the volume of product data was expanding quickly, which gradually brought out the drawbacks of Excel in data management,” says Liu Xingyin. ”This included the lack of a unified system for numerous disconnected datasheets; poor integration with other systems that contain cost-related information; difficulty in design data sharing, in archived data query and referral; poor costing efficiency, etc.

“Besides, throughout the production cycle of a product, each team produces their own product-related information, and requires frequent information exchange with other teams in order to support informed innovations related to the product. Under these circumstances, the workload in our department kept expanding while our efficiency kept getting worse.”

Product-centered data management

“When I was communicating with someone from abroad, by chance I found out that they had been using the Teamcenter solution for product costing, and that’s when we got in touch with Siemens Digital Industries Software,” says Liu Xingyin. “We found that the database architecture of Teamcenter is basically identical to ours; in fact, some process breakdowns in Teamcenter are even more detailed, and we use the same computational logic in all parameters.

“Nevertheless, we still had many concerns about actually implementing the Teamcenter solution for product costing, and our greatest concerns included whether the open architecture of Teamcenter would support importing our existing data, whether we could modify data in it, and whether we could customize development based on our own workflows.”

But the professional implementation team from Siemens Digital Industries Software soon allayed the concerns of Weichai Power.

“The technical experts from Siemens Digital Industries Software were so professional and efficient that they managed to accurately understand the business features and advantages of Weichai Power in merely a few months, and tailored a platform solution to our business features using the powerful customization and secondary development functions of Teamcenter,” says Liu Xingyin. “Now we have imported the existing data and value models of our own.

Now that using the Teamcenter solution for product costing has enabled value optimization across the entire value chain, Weichai Power is able to get accurate and traceable cost calculations in a timely fashion, promote collaborative product design, improve data accuracy and quality, reduce man-made change errors and improve the execution efficiency of the design change process. So far Weichai Power has applied the Teamcenter solution for product costing to purchase price analysis, target costing, profitability calculation, design-to-cost, open book negotiation, as well as reducing costs and increasing efficiency.

For instance, using the profitability calculation enables Weichai Power to secure product investments by predicting future unit costs and prices over the entire product lifecycle. Using open book negotiation, Teamcenter helps Weichai Power negotiate with their customers by enabling them to leverage optimized but comprehensible cost data in customized formats. By presenting a clear cost structure and plausible break down of the product costs, Weichai has a stronger negotiating position.

“The value models we had established for our product parts could only compare work pieces one-on-one, which made it very inconvenient and inefficient to search for parameters of an individual working procedure,” adds Liu Xingyin. “But Teamcenter provides comparisons between manufacturing processes, enabling more accurate cost calculation.

“By using Teamcenter we have solved the product inconsistency problem, maintained product quality (precision) and significantly improved working efficiency. In addition to doing new projects, we’re also using Teamcenter to repeatedly verify and compare previous products, which enables us to discover any problems existing in those previous products while correcting inaccurate data. And then we develop cost-reducing and efficiencyincreasing measures based on these problems and set a target rate for cost reduction in each department.”

Today Weichai Power is able to keep the value costing deviation under five percent, effectively strengthening its corporate competitiveness.

Higher goals driven by PLM

“Currently we are only using the product cost management function of Teamcenter, though Teamcenter provides a holistic PLM solution,” says Liu Xingyin. “At Weichai Power, the Department of Value Engineering is in charge of centralized management, so in our next steps we’re hoping to extend the other functions of Teamcenter, to realize collaboration and communication among different departments like development, technology, production, purchase, sales and finance.”

“Product cost management is a valuable solution empowering an enterprise to compete in the market,” said Liu Xingyin. “In an increasingly competitive market environment, and in the face of more and more grim challenges such as how to increase a product’s market competitiveness and how to heighten customer satisfaction, more often than not enterprises resort to strategies like maintaining effective management over the product development process, reducing time-tomarket and time-to-volume, improving working efficiency, establishing re-use and safe management mechanisms for R&D results, and realizing exchange and integration of information and data.

“In fact, before the launch of every new product, we would figure out the design cost according to the overall market condition, and then set the final sales price based on the purchasing cost, manufacturing cost and product quantity. By developing a value analysis throughout the value chain, we can ultimately realize clear and transparent cost management. As a result, Teamcenter has not just helped us reduce the purchasing cost, but it has enabled us to effectively avoid unscrupulous competition among suppliers and to maintain product quality and attain sustainable development.”

To a large extent, the great achievements of Weichai Power are attributable to its unswerving insistence on applying product value analysis. As Weichai Power pursues sustainable development, the powerful Teamcenter product lifecycle management module is playing a critical role.

As a result, Teamcenter has not just helped us reduce the purchasing cost, but it has enabled us to effectively avoid unscrupulous competition among suppliers and to maintain product quality and attain sustainable development.