Automotive manufacturer uses Simcenter Amesim to smooth out the cold start of its diesel engine

Siemens Digital Industries Software solution enables Renault to reduce analysis time compared to test-only studies

Renault

Renault is a French multinational vehicle manufacturer that was established in 1899, and produces a range of cars and vans. In 2012, Renault employed more than 127,000 people, had a presence in 128 countries and realized global after-sales revenue of over 4 billion euros.

- Sede centrale:

- Boulogne-Billancourt, France

- Prodotti:

- Simcenter Amesim software

- Settore industriale:

- Industria automobilistica e dei trasporti

This type of first-order approach is extremely effective and couldn’t be done quicker or at a lower cost without the use of such innovative software as Simcenter Amesim.

Seeking a smooth start

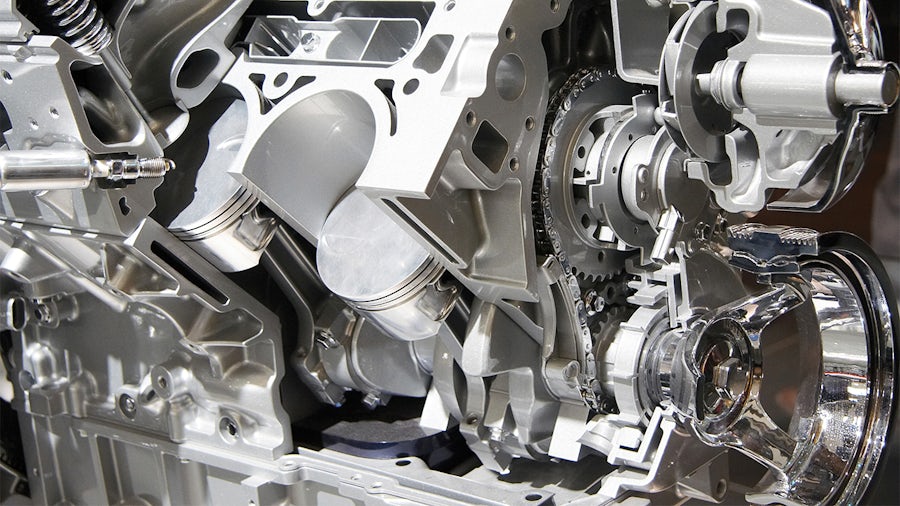

Engines and gearboxes have to be developed in less time than ever before to meet the challenging time-to-market deadlines set by automotive original equipment manufacturers (OEMs). To save time, the team at Renault eliminated a seemingly unnecessary design iteration. However, that affected the drivability of the automobile, an important brand differentiator. To solve the issue, the team turned to simulation to smooth out the kinks in its four-cylinder, 2.0L diesel engine design.

Specifically, the team honed in on the fun-to-drive factor known as the cold start. Starting a diesel engine sounds rough compared to a traditional combustion engine. There were quite a few variables to examine in terms of how to improve the cold start, such as fuel choice, starter and battery, injection system, chamber temperature, combustion efficiency and engine friction.

However, the team was not convinced that any of these variables played a critical role in the problem, so they decided to examine the mechanical resonance of the rotating parts, especially the dual mass flywheel (DMF). Modern diesel engines generate high torque so they need extra smoothing out or damping to maintain good drivability and avoid engine coughs and sputters during cold starts. In modern diesel engine architecture, a DMF helps even out the torque charges, but oscillations can still occur since the DMF is greased. That can affect the driveline, especially during cold starts when the viscosity coefficient of the oil is not the same as when it is warm. The result is a very different, non-linear behavior of the DMF.

“Driving pleasure is generally not the main reason to purchase a car, but it can be the main reason to buy another one,” says Michel Gizard, a torque transfer expert at Renault.

Simulating the DMF

The DMF is composed of two flywheels connected by a set of long springs working in grease. There are three elements to the DMF: the first flywheel is connected directly to the crankshaft; the second flywheel is connected to the clutch and in between, there are curved springs. One of the issues is that the springs are floating in grease. It is this grease that is responsible for the cold start issue.

The team at Renault developed an in-house model to obtain very accurate results (within the 0 to 200 Hz frequency domain). This level of accuracy was achieved by working on a one-dimensional model describing the dynamics of curved springs in the DMF. Modeled as distributed elastic elements, the springs are subject to dry friction and inertia forces, and they can move between the primary and secondary flywheels. The forces exerted on the curved springs determine the torque in the DMF, affecting the total time of the engine startup.

The Engine and Transmission Design team at Renault had been using Simcenter™ solutions from Siemens Digital Industries Software for years. When the team wanted to understand the phenomena behind the results, it turned to Simcenter Amesim™ software for simulation solutions. System simulation proved to be the best way to have a complete overview, integrating test and simulation together in the design process. Testing allowed the team to get measurements and results, and simulation enabled the team to understand the phenomena behind the data. This enabled the team to translate the influence of each subsystem and component on the whole system.

“Simcenter Amesim is the ideal tool to analyze the measurements acquired by test,” says Gizard. “It enables us to answer the questions raised by test measurements, like translating the signals into physics and interpreting the signals.

“We greatly appreciate Simcenter Amesim because it lets us study dynamics and transient phenomena, and couple several physical domains together. Simulation is now driving the test measurements that we perform.”

Achieving satisfactory behavior during a cold start means taking mandatory preventive measures, and it requires the precise assessment of the mechanical impacts on the overall architecture. Simulation allowed the team to differentiate real recurrent physical phenomena from just sensor noise. The team realized a significant gain in analysis time compared to test-only studies, and the fact that all the ready-to-use models of Simcenter Amesim can be rapidly assembled to create complex systems proved to add significant value.

Beside the modeling capabilities, Simcenter Amesim comes with various, high-level analysis tools that allowed Renault engineers to run frequency analysis for vibration modes identification, which is essential to guarantee the quality of simulation.

“This type of first-order approach is extremely effective and couldn’t be done quicker or at a lower cost without the use of such innovative software as Simcenter Amesim,” says Gizard.

To study the behavior of the mechanical parts, a complete setup was built with a test bench, including:

- Four pressure sensors

- Engine speed measured on the starter ring

- Secondary flywheel speed

- Crankshaft pulley angle

- Alternator speed

- Starter current and voltage

- Battery current and voltage

We greatly appreciate Simcenter Amesim because it lets us study dynamics and transient phenomena, and couple several physical domains together.