Delivering product development knowledge automatically to the customer

With Teamcenter HASCO creates a web store with more than 100,000 articles in less than one year

HASCO

HASCO develops and produces over 100,000 products that provide individual, simple and economical solutions for tool and mold making and the plastics processing industry. The complete range of ready-toinstall system components is offered with comprehensive support in application and implementation.

- Sede centrale:

- Lüdenscheid, Germany

- Settore industriale:

- Macchinari industriali

Our catalog has never been as good as it is now. We have eliminated inaccuracies that have gone unnoticed for decades.

Complete range of system components

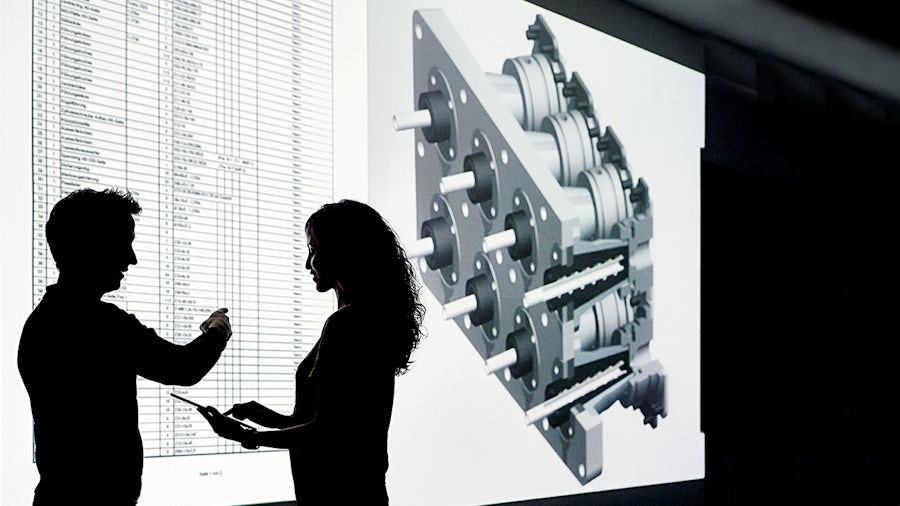

HASCO Hasenclever GmbH + Co KG, based in Lüdenscheid, Germany, began developing and producing press and injection molds for the emerging plastics industry soon after the company was founded in 1924. In 1962, under Rolf Hasenclever, a modular system of standard components was introduced, laying the foundation for uninterrupted growth. Today, the company employs over 650 people at 35 locations worldwide. The product range comprises over 100,000 components that provide individual, simple and economical solutions for tool and mold making and the plastics processing industry. The complete range of ready-to-install system components is combined with comprehensive application support.

PLM as the basis for a new web store

In addition to hot runner systems, nozzles and temperature control systems, HASCO products include highly standardized and adaptable components as well as individual solutions developed jointly with customers. From the end of 2014 to the end of 2015, HASCO undertook a product lifecycle management (PLM) project to make its product range available via a customer portal on the Internet. As a prerequisite, a new system landscape had to be created. For the web store, HASCO selected a future-proof software system that could build on commercial and logistics information in the company’s enterprise resource planning (ERP) system.

HASCO needed a product data management (PDM) solution to more effectively control the millions of data items created by its computer-aided design (CAD) systems. Because HASCO uses another 3D CAD system in addition to NX™ software from Siemens Digital Industries Software, the desired PDM solution had to be multi-CAD compatible, without limiting users to a single CAD provider. For this reason, HASCO chose Teamcenter® software from Siemens Digital Industries Software. “The entry-level version of Teamcenter was affordable and quickly dispelled our concerns that Teamcenter was too big for a medium-sized company,” explains Dirk Wollborn, development designer and project manager at HASCO.

Teamcenter implemented in two months

The Teamcenter solution includes preconfigured process management and user roles as well as functions and elements based on best practices for mechanical engineering. It can be easily adapted without programming knowledge, which also reduces the external service effort required for implementation. At HASCO, rapid availability was particularly important, as just less than a year remained between the first workshop at the end of 2014 and the planned go-live of the web store.

“The preconfigured solution facilitates an agile implementation project without detailed specifications and thus saves two to three months of planning and theoretical discussions,” says Wollborn. “During the installation we were able to understand many interrelationships and thus better transfer our requirements to them. Missing elements and relations could be added later without loss of time.” In this way, an internal team of six people began to configure the standard elements, add the attributes they needed and transfer their properties to new processes and elements by inheritance. A few weeks later the revisionable storage with process management and access control was implemented.

Data quality: the key to digitization success

Next the basic product data had to be processed. The data includes a master data record for each product and a detailed data records for associated dimensions, each of which is assigned an ERP number. Four external employees extracted this information from the existing CAD data and saved it in comma-separated values (CSV) tables that were imported into Teamcenter.

“We quickly realized that our database, which had grown over 50 years, no longer met today’s demands for simplicity and clarity,” explains Wollborn. “We took the opportunity to clean up the order numbers, and to create clear, unambiguous data according to precise factory standards, down to the upper and lower case when assigning variables and designations.”

Many attributes derived from technical contexts are required for marketing, and had to be added to the tables. Many of these are represented by variables used to automatically generate product variants. Much of the data is automatically entered into the Teamcenter classification as new designs are created; designers select the correct variables in accordance with the factory standard from a database.

In the course of data cleansing, the hundreds of pages of printed catalogs of all HASCO products were digitized and harmonized with the CAD tables. “Our catalog has never been as good as it is now,” says Wollborn. “We have eliminated inaccuracies that have gone unnoticed for decades.” CAD data and production drawings had to be uniformly redrawn according to a new standard and entered into Teamcenter. The data overhaul also enabled automatic creation of data for the web store. “The rapid implementation of Teamcenter enabled us to deliver all the technical information required for the web store on time,” says Wollborn. “Many processes have already been automated and technical functions were implemented that are required in the web store.”

Teamcenter as a technical data hub

Teamcenter forms for the web store describe the order in which the attributes of a product are to be offered for selection, and which filter functions are available. To ensure that the selection of over 100,000 products leads to meaningful overall solutions, six different forms of dependency on related articles have been created, such as identical in construction, associated or alternative, and are captured in Teamcenter. These relationships are displayed at the bottom of the product pages in the web store to facilitate orientation and complete ordering for the customer.

To enable customers to integrate the standard mold components into their own designs, 3D product models are offered in numerous neutral and manufacturerspecific CAD formats. The models can be generated on request based on the tables in Teamcenter. Sales partners also receive standard parts libraries with 3D models via data exchange that is also managed by Teamcenter.

The web pages include logic data in the form of an assembly assistant for configuring custom designs. “In addition to the standard product range, customers can quickly and easily configure their own mold assemblies online,” explains Wollborn, who developed the assistant. “In solving the numerous tasks, I have never reached the limits of Teamcenter capabilities.”

Successful digital transformation

The automated routines and processes, from product development through the production of components, save time and help eliminate errors. “Teamcenter has brought us clear, comprehensible processes with considerable control mechanisms,” summarizes Wollborn. “At the same time, all employees have a knowledge base that promotes our brand value based on know-how and consulting quality.“ Around 900 product groups with up to 10,000 possible variants are managed with Teamcenter − in addition to 57,000 CAD models, 3,500 Microsoft Office documents and 17,000 PDF files. Almost 800 product master relations and 3,000 forms support the web store.

“With enormous growth figures, the new store transfers the order volume that was previously received via the manually operated telephone and fax into a secure, digital sales channel,” summarizes Wollborn. More than 40 employees in the areas of product development, application technology, purchasing and production work with Teamcenter every day without errors or problems.

The entry-level version was affordable and quickly dispelled our concerns that Teamcenter was too big for a medium-sized company.