Power distribution equipment manufacturer uses Solid Edge to enhance design efficiency and manufacturing processes

Siemens Digital Industries Software solution enables CREAT to make a seamless transition of its product R&D platform to 3D CAD

CREAT

Beijing Creative Distribution Automation Co., Ltd. (CREAT), founded by the China Electric Power Research Institute in 1988, is now a major high-tech enterprise in the China Torch Program, Beijing Municipality Hi-tech Enterprise. CREAT is strongly supported by the 10-100-1000 Project of the Zhongguan Village National Innovation Demonstration Zone.

- Siège social:

- Beijing, China

- Produits:

- Teamcenter Integration for Solid Edge

- Domaine d'activité:

- Énergie et Services Publics

Around the year 2000, most foreign enterprises had begun using 3D design software and some high-end enterprises also began promoting 3D design software. So we realized the necessity of 3D design software in the technical development of an enterprise and hoped to improve our core competencies by introducing it.

Advancing power distribution systems

The practices of Beijing Creative Distribution Automation Co., Ltd. (CREAT), a technology-oriented power distribution equipment manufacturer, in selecting and applying its 3D computer-aided design (CAD) system provides an excellent example for various types of enterprises.

CREAT, founded by the China Electric Power Research Institute in 1988, is a major high-tech enterprise in the China Torch Program, Beijing Municipality Hi-tech Enterprise. CREAT is strongly supported as part of the 10-100-1000 Project of the Zhongguan Village National Innovation Demonstration Zone, and is a major enterprise in Haidian District. According to 2014 statistical data, the operating income realized by CREAT for the report period is ¥1.348 billion, representing year-over-year growth of 35.67 percent.

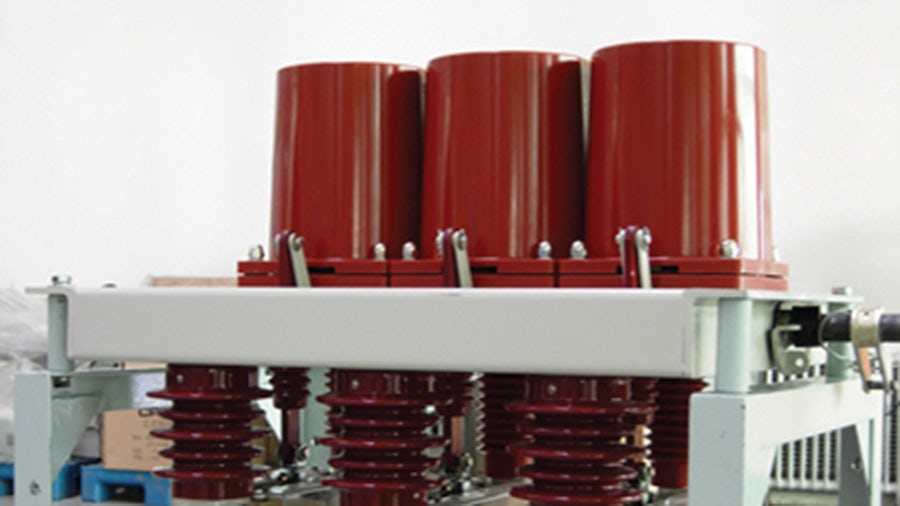

For more than 20 years, CREAT has focused on advancing power distribution systems. Its technically innovative products include box-type substations and outdoor ringed network switchgears (used in the United States and Europe), amorphous alloy transformers, vacuum switchgears for permanent magnetic mechanisms, vacuum reclosers for permanent magnetic mechanisms, on-post load switches, failure indicators, power distribution terminal units, glass reinforced concrete environment- friendly cabinet bodies and mediumvoltage cable accessories.

CREAT has five product categories: low-to-medium switches, power distribution transformers, power distribution automation devices, cable accessories and static reactive compensators. These products are widely used in power distribution networks all over China as well as in sectors such as railway, metallurgy, petrochemical, coal mining, wind power generation and photovoltaic power generation.

The challenges of 2D

“In order to improve the design and manufacturing efficiencies of switch cabinet bodies, CREAT hoped to conduct simulative calculation with 3D sheet metal design, and automatically transition to numerical control (NC) machining equipment to avoid possible programming errors and improve production efficiency,” says Mr. Liu Daxiang, director of the chief engineer office at Beijing Creative Distribution Automation Co., Ltd.

According to Liu Daxiang, 2D design software is not intuitive. With 2D design software, it is impossible to check the assembly relations or collisions between parts, effects of entities, etc. It is time-consuming to draw assembly drawings. Use of standard parts is not a normal practice. It is impossible to properly reflect parametric designs in 2D design software, and this results in poor design efficiency. In addition, products designed with 2D design software are not as intuitive or effective as those designed with 3D design software.

“Around the year 2000, most foreign enterprises had begun using 3D design software and some high-end enterprises also began promoting 3D design software,” says Liu Daxiang. “So we realized the necessity of 3D design software in the technical development of an enterprise and hoped to improve our core competencies by introducing it.”

CREAT’s portfolio is reasonably complete. Although the mechanical structures of the company’s products are not complicated in themselves, they are highly precise and reflect superior quality. Therefore, the CAD system must have excellent capabilities, such as for designing sheet metal.

Most users of CREAT products are electric power authorities or power companies. After undertaking power station construction projects, these organizations will order products from CREAT. Upon receiving an order, CREAT organizes design and production activities according to product categories and customer requirements. CREAT’s business reflects two special characteristics: customer requirements are inflexible and the customers typically set the delivery times, and the technical details of the power station usually aren’t finalized until the project is well underway. CREAT typically begins producing parts for the project and continues tweaking until the solution has been finalized.

Although CREAT’s business features highmix, low-volume production and assemblies to order, relatively more complex user requirements require CREAT to carry out design and production activities simultaneously. As a result, the 3D CAD system not only needs to readily handle significant amounts of design work, but it also needs to engender collaboration across information systems.

The introduction of Solid Edge has significantly changed the product R&D process at CREAT.

CREAT chose Solid Edge mainly because it not only fully meets its requirements for a 3D CAD system in terms of performance, ease of use and collaboration, but it also features a compelling performance/price ratio, has been proven through extensive industry application and possesses outstanding advantages in sheet metal design.

First, using Solid Edge has enabled a quick and seamless transition of CREAT’s product R&D platform to 3D, which significantly increases individual user efficiency, streamlines data conversion and improves design collaboration across the group.

Easy-to-use, efficient and so much more

After careful and comprehensive consideration of its business processes and how the 3D CAD system could best meet its needs, CREAT defined clear and definite system requirements. The system needed to be simple, easy-to-use, efficient, specific to its domain and fully suitable for its entire business process. The winning technology must be able to effectively manage product data, support process planning and be readily integrated with enterprise resource planning (ERP) and other information systems for optimal collaboration.

“In July 2003, we officially signed the purchase contract and began using Solid Edge®,” says Liu Daxiang. “It was subsequently upgraded in June 2004 and November 2006, and we upgraded again in 2009.”

Compelling price/performance ratio

CREAT chose Solid Edge® software mainly because it not only fully meets its requirements for a 3D CAD system in terms of performance, ease of use and collaboration, but it also features an exceptionally compelling performance/price ratio. The software has been proven through extensive industry application and possesses particularly outstanding advantages in sheet metal design.

With Solid Edge, CREAT’s clear favorite to achieve its business and productivity goals, the company was also quite pleased with the comprehensive technical support capabilities and track record of Beijing Henghua Chuangyi Co., Ltd., a partner of Siemens Digital Industries Software.

CREAT initially used Solid Edge to design switch products. Now it is being used to design all CREAT products. The introduction of Solid Edge has significantly changed the product research and development (R&D) process at CREAT.

First, using Solid Edge has enabled a quick and seamless transition of CREAT’s product R&D platform to 3D. This not only improves product R&D efficiency, but also provides sufficient room and technical support for improving data conversion and design collaboration efficiencies.

Second, as a powerful top-down design tool, Solid Edge is able to better manipulate complex large assembly designs. When combined with its synchronous technology, users can easily re-use existing internal models as well as suppliers’ models, thus significantly accelerating the product design process.

Third, for switch industry players such as CREAT that mainly produce sheet metal parts, best-in-class sheet metal capabilities are essential for product R&D productivity and innovation. Thus, the sheet metal capabilities of Solid Edge – for example, stock framework design and sheet metal unbending – are important to the needs of CREAT. In addition, the sheet metal mode of Solid Edge can easily be switched to the part mode at any time. Solid Edge enables CREAT to easily switch between two modes during the product development process, fully meeting the desire of engineers for highly agile development.

Fourth, Solid Edge provides an embedded standard parts library and supports the design of typical mechanical parts. Solid Edge is used to automatically generate parts and design parameter files as soon as engineers directly call or input parameters. Furthermore, Solid Edge can automatically generate accurate three-view projections and section views. This not only reduces manpower requirements, but also increases efficiency and accuracy in final engineering drawings, as well as eliminates unnecessary wait times for subsequent process designs and manufacturing/ production operations.

Impeccable record of on-time order delivery

By implementing Solid Edge, CREAT has quickly and efficiently completed the transition to a 3D CAD design platform while increasing the re-use of the corporate repository. The result has been enhanced interoperability between CAD system and other information systems. With Solid Edge, CREAT has dramatically reduced R&D cycle time as well as achieved an impeccable record of on-time order delivery.