How to drive the ship design process via simulation tools

A simulation-driven approach to ship design can reduce costs and speed up design times. Learn how to meet your targets with confidence.

The marine industry is under continuous pressure to improve vessel efficiency and reduce emissions. The only possible strategy for both shipyards and ship owners to ensure targets are met is to design, then build the most efficient ship possible. The greatest impact on increasing vessel efficiency and reducing costs can be made during the ship design phase.

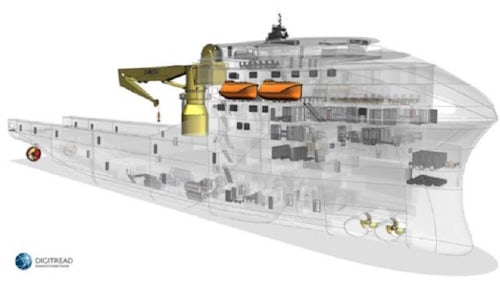

In this white paper, we introduce the simulation-driven ship design process, a new approach that moves away from the inefficient ship design spiral and instead makes full use of the digital technology available today. Naval architects can evaluate many more designs and focus on improvements or novel solutions to find the most efficient design.

Ship design basics with an integrated approach

The traditional ship design process typically starts with a mission statement for the new ship and the process then looks at many different aspects of the design in turn, such as proportions, hull form, general arrangement, structure, and ship weight, etc. Often these evaluation stages are performed by separate teams with no link between the tools they use or the data produced. Any changes in requirement or ship design require all aspects to be re-examined, but because of the delay in data transfer, detailed analyses often lag behind the current design. This process increases pressure on profit margins and reduces the time available to create the best possible design.

The simulation-driven ship design process outlined in this paper rethinks ship design basics. The method uses connected analysis tools and centralized data storage to remove silos and connect all analysis stages to one central master model. Teams have access to the required data and can always work on the current design. This enables faster design updates and integrated analyses.

Reduce costs and design time by skipping the ship design spiral

Our solutions provide an integrated design environment, automated workflows, and intelligent design exploration tools. Working in this way removes the traditional ship design spiral by removing the separate steps and streamlining the process. This enables the rapid analysis of many design variants and an increased understanding of ship performance from the earliest design stages. The reduction in manual intervention frees up naval architects to focus on results analysis and design alterations.

CAD boat design case study

Learn how intelligent design optimization enables you to meet specified requirements and gives you confidence in submitting tender bids. This paper contains a CAD boat design case study, which shows how to optimize a vessel, by specifying a range of requirements and exploring designs that fit within the criteria. The automatic design process analyses hundreds of designs, giving ship cost estimation and performance data for each one. By analyzing trends and patterns in the results, you can see the effect of different parameters on ship performance.

Learn more about the author:

Dejan Radosavljevic is the marine industry expert for the simulation and test segment of Siemens Digital Industries. He spent over 20 years at Lloyd’s Register of Shipping where he held a variety of roles within the Technical Investigations Department, and fluid dynamics group. Dejan has championed the use of marine CFD throughout his career, particularly for ship performance optimization. In his role at Siemens, he works with marine customers worldwide, helping in applying simulation to their ship design and performance processes.