How Siemens NX improves prosthetics design

The demand for prosthesis is increasing, and medical companies are seeking ways to design these complex and personalized prosthetics. New technology, materials and manufacturing processes enable the development of medical devices that are more affordable, comfortable and faster to product.

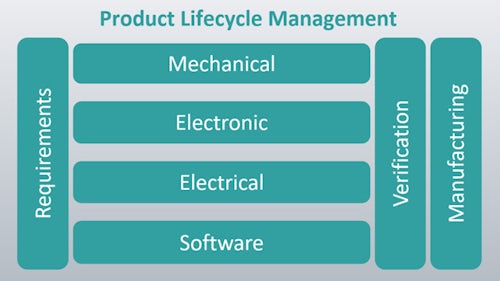

Siemens NX software allows medical device companies to innovate and realize the benefits of the next generation of product design. NX delivers a virtual design approach that integrates mechanical, composite and additive manufacturing to open opportunities for the development of prosthetics.

Read the free white paper to learn more about developing prosthetic design with NX.

Trends in the world of prosthetics

Prosthetics of today are becoming more intricate and individualized. Businesses must develop and innovate their goods and design methodologies to stay competitive. The need for prosthetic devices is rising globally, which is increasing competition amongst medical device businesses.

To match consumer demands, businesses are motivated to increase their products' comfort, cost, and customization to meet a client's needs. When it comes to patient comfort, prosthetics are getting lighter and more durable, which increases patient wearability and makes the device feel more like a natural limb. Comfort is paramount. Consumers want personalized prosthetics that let them feel at ease and are aesthetically adapted to their preferences.

Benefits of integrating NX design software with prosthetic design

NX seamlessly integrates design, simulation and manufacturing within a single platform. The software enables faster innovation and optimization while reducing the cost of the product. NX enables medical device manufacturers to quickly refine models in one environment with significant productivity improvements.

Utilizing feature tools in NX modifies the design to the personalized look that each patient wants. Want to create a prosthesis for athletes in track and field? Perhaps a carbon fiber casing would be suitable for the athlete. NX opens the door when it comes to creating products with materials that are lighter and at less cost.