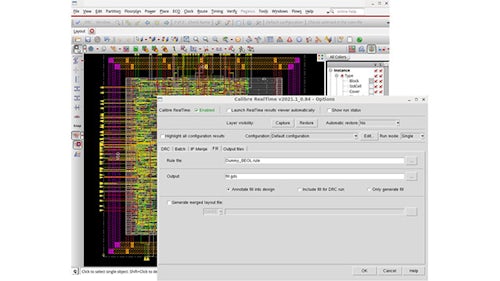

Implementing signoff metal fill in the P&R design environment for faster and more accurate tapeouts

Calibre RealTime Digital enables signoff and ECO metal fill in P&R during physical verification closure

Adding inactive metal fill is a mandatory step in the P&R design flow. The Calibre RealTime Digital interface provides push-button access to the Calibre YieldEnhancer with SmartFill functionality in the P&R environment. When running signoff DRC in P&R using the Calibre RealTime Digital interface, designers can check the interaction of the design and fill shapes, and make quick edits to fix any DRC errors without having to exit the P&R environment. They can also use the resulting signoff fill in downstream flows (such as extraction and timing) without having to leave the P&R environment. The Calibre YieldEnhancer ECO SmartFill flow is run outside the P&R environment, but P&R engineers can import the ECO fill Incremental DEF created by the Calibre YieldEnhancer ECO SmartFill run. The Calibre YieldEnhancer ECO fill flow reduces the runtime and timing impacts of ECO changes by only generating fill around the ECO change regions, which can ultimately reduce mask costs.