white paper

Fix DFM hotspots in P&R with Calibre sign-off confidence

DFM hotspot detection and fixing with signoff-quality verification during P&R

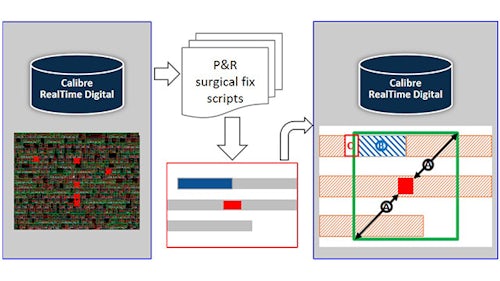

The GLOBALFOUNDRIES DFM-POP in-design fixing flow uses Calibre Pattern Matching technology to find DFM hotspot patterns in layouts. Adding the Calibre RealTime Digital API to this flow enables fast Calibre signoff-quality checking of hotspot fixes in the P&R environment, significantly accelerating DRC closure schedules while providing Calibre confidence.