Enhancing guard ring verification for latch-up prevention at advanced nodes

Guard ring verification at advanced process nodes

Verifying the existence and accurate construction of guard rings around aggressors and between potential victims using electronic design automation (EDA) tools is a standard physical verification process. However, at advanced process technology nodes, smaller geometries with higher density per unit area, more narrow and resistive interconnect, and the use of multiple power domains make latch-up prevention and guard ring verification more challenging than ever.

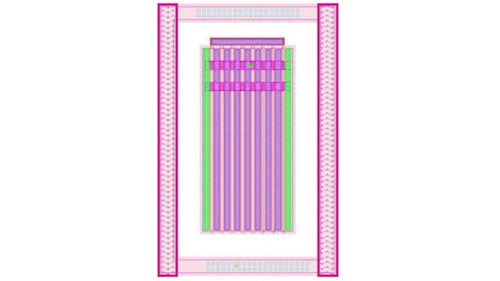

The Calibre PERC reliability platform can automatically identify intentional layout devices with diffusion regions, as well as biased guard ring structures placed around potential injector devices typically connected to I/O pads, using circuit topology tracing to identify specific nets or devices that represent paths to the pads, so these paths can be evaluated for the presence of guard rings. The Calibre PERC platform can then perform a variety of point to point (P2P) and path resistance measurements for each guard ring, automatically adding voltage information to the path for detailed analysis. It also uses a static solver to produce current density data for evaluating the guard ring resistance by layer. Together, these capabilities enable design teams to confirm their guard ring structures provide the intended protection against latch-up.