white paper

Better prediction on patterning failure mode with hotspot-aware OPC modeling

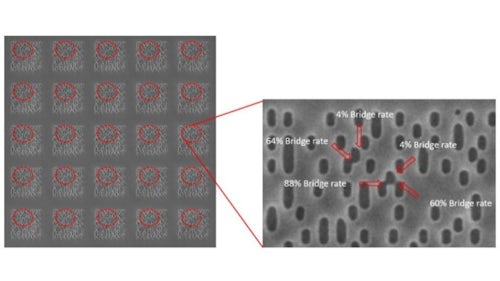

Our method includes a new sampling plan with additional hotpot locations and the corresponding contours input data, which improves the coverage of the OPC model and the accuracy of the after development inspection (ADI) pattern hotspots prediction, such as trench pinching or bridging in complex 2D routing patterns.

A hotspot-aware modeling flow based on LFoV images/contours not only benefits users by improving the capture rate of the lithography defects, but also brings the advantages to the failure mode analysis for the post-etch stage.

The preliminary inspected hotspots can be added to the traditional OPC modeling flow in order to provide extra information for a hotspot aware OPC model. We apply a compact optical/resist 3D modeling toolkit to interpret the impact of photoresist profiles, as well as accurate predictions of hotspot patterns occurring at the top or bottom of the photoresist.

We also introduce a contour-based modeling flow that uses a site or edge-based calibration engine to better describe hotspot locations in the hotspot-aware OPC model calibration. The improvement in pattern coverage in the modeling flow is described through feature vectors (FVs) analysis and comparisons between the conventional and the hotspot aware OPC models is also presented.

The time and cost of using conventional critical dimension scanning electron microscope (CD-SEM) metrology to measure such a large amount of CD gauges are prohibitive. By contrast, when using LFoV e-beam inspection with an improved training algorithm to extract fine contours from wafer hotspots, a hotspot aware OPC model can predict ADI hotspots with a higher capture rate as compared to main feature OPC model.

A version of this paper was originally presented at the IEEE SPIE 2021 conference and published in the proceedings.