Automated design-aware optimized fill ensures both timely design closure and design reliability

Automated identification of critical or sensitive nets and devices in IC designs for enhanced protection during fill insertion

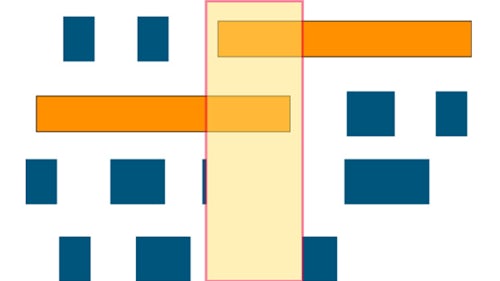

Automated circuit recognition is needed to capture complex topologies that can quickly and accurately identify critical nets in the design. Combining context-aware analysis with functionality such as circuit pattern matching is an innovative approach that can speed up and automate processes like the identification of critical nets and devices while allowing for potential variations in circuit schemes. Identifying critical nets in the netlist, finding corresponding geometries, and generating geometrical marker layers can be automated, and the results used to inform the fill process, significantly reducing the time and resources required. To save even more time, designers can re-use the output database created in the LVS run to obtain the design layout netlist. This combination of multiple functionalities enables the automated identification of critical or sensitive nets and devices for enhanced protection during fill insertion.