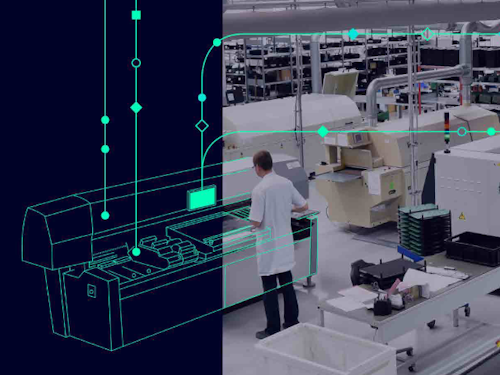

Smart inventory management for manufacturing

Opcenter Intra Plant Logistics ensures materials are always available when needed, in the right place, at the right time

Logistics management inside the factory is a comprehensive undertaking, requiring multiple strategies to efficiently keep track of your inventory. The Opcenter Intra Plant Logistics (IPL) solution based on the production schedule, actual demand and live material consumption. It offers a flexible solution to address your specific production needs, helping you to significantly reduce inventory, maintain material specification, optimize your warehouse activities, and ensure a smooth manufacturing flow.