Standardizing and digitalizing processes to increase production efficiency, reduce waste and enhance data quality

Polipak uses Opcenter Execution Process and Opcenter APS to operate more flexibly, efficiently and sustainably

Polipak

Polipak Sp. z o.o. is one of the leading manufacturers of bags, foil sheets and foil sleeves. It offers products for households and businesses operating in various sectors.

https://polipak.com.pl/en/strona-www/

- Headquarters:

- Środa Wielkopolska, Poland

- Products:

- Opcenter APS, Opcenter Execution Process

- Industry Sector:

- Consumer products & retail

Using Opcenter thus supports strategic decision-making, enabling us to respond quickly to changing customer needs or circumstances.

Leveraging an established and trusted reputation

Bags, including refuse sacks, plastic films and tube sleeve foils, are undoubtedly indispensable everyday products and are used in most households and in many industries by employees and companies in the food and beverage, retail and construction sectors. Headquartered in Środa Wielkopolska, Poland, Polipak Sp. z o.o. is a leading manufacturer in central and eastern Europe and is part of the Sarantis Group, which has built a strong brand trusted by millions of consumers. Standing out with its broad range of products, including standard and tailor-made solutions, the company plays a key role in the market by specializing in producing various plastic film products.

Digitalizing to achieve dynamic company growth

The Sarantis Group attaches great importance to sustainability as the key element of its business strategy. Thus, Polipak constantly strives to increase production efficiency, reduce costs and minimize its environmental impact while maintaining the highest product quality, which is the company’s consistent differentiator on the market.

To keep improving processes and further strengthening their market position and sustainable development in line with the spirit of modern technologies, Polipak required systems that comprehensively manage production processes, automate reporting and optimize resource use. Additionally, they needed to implement and integrate systems to ensure the necessary seamless compatibility between the existing systems and the individual divisions and companies of the Sarantis Group operating in various regions of the world.

With the rapid growth in production volume and the increasing number of machines, Polipak needed to shift to more advanced planning and management tools. In terms of production efficiency and resource optimization challenges, it showed that traditional methods, such as manually filled-in data sheets, were becoming ineffective.

To accomplish this, Polipak teamed up with ASKOM, a Siemens Digital Industries Software partner, to implement Opcenter™ software for advanced planning and scheduling (APS) and as a manufacturing execution system (MES). Additionally, Opcenter is part of the Siemens Xcelerator business platform of software, hardware and services.

“We needed a solution that would provide full traceability and control at every stage of production,” says Andrzej Migda, information technology (IT) systems consultant at Polipak. “Our objective was to integrate modern digital solutions to better manage the complex process of multistage production. Thus, we subsequently integrated the APS and MES from Siemens, which became key to the growth of the company.”

-640x360.jpg?auto=format,compress&w=843&q=60)

Optimizing processes and minimizing waste

The three key departments operating within the company, the Foil Department, Roller Department and Regranulation Department, as well as the equally important central dosing system, are closely interlinked as part of a multistage production process. It begins with a fully automated process for preparing batches of input granulate mix consisting of a dozen or so raw materials, additives and dyes for each extruder separately, including for the three-layer machines for every screw in the central dosing system. As a fully automated process, the system transports and delivers the ready-made charge of the raw material mixture to the specific screw in the extrusion machine. Once it starts up the raw material feed, it produces a foil on the extrusion machines, winds it onto bales and then transports it to the foil warehouse. When it needs the foil for producing bags, it is transported to the Roller Department, where it produces the finished products. These foil and bag production processes generate waste. Although Polipak has been successful in cutting down the amount of waste, at current production levels, they generate around 5,000 metric tons per year. Such a large amount requires efficient recycling so that it can be reused in the production process.

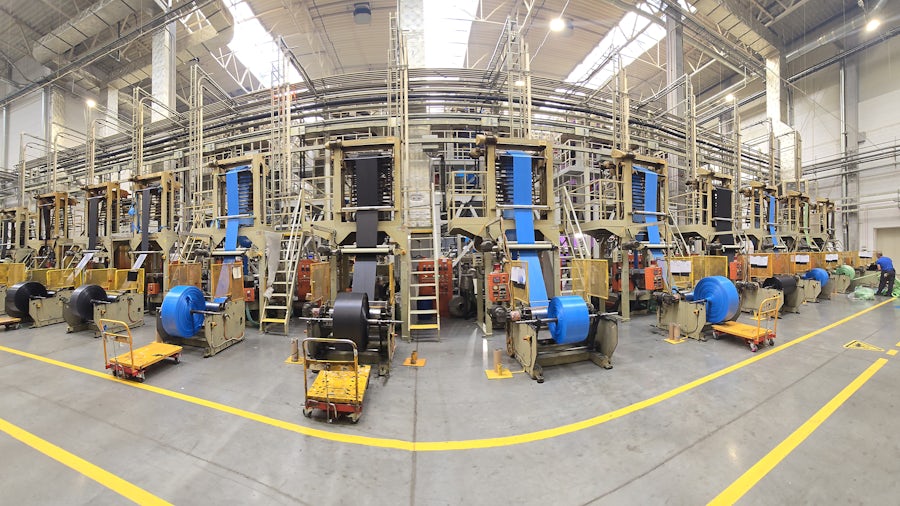

When beginning to implement bespoke digital solutions from Siemens, Polipak was operating a production facility equipped with, among other things, 67 extruders (including three-layer and two-layer machines, which is a total of 95 screws) in the Foil Department, 32 machines in the Roller Department, automated packaging lines, machines for producing regranulate (a type of plastic made from recycled materials) from waste and an automated central dosing system for feeding extruders raw material.

The advanced production planning and management tools, suitable for their large and ever-growing scale of operations, were essential to ensure a smooth system operation. With Siemens solutions, Polipak can effectively manage its complex infrastructure and optimize production, purchasing and sales processes, as well as minimize

raw material waste.

-640x360.jpg?auto=format,compress&w=843&q=60)

Supporting strategic decision-making

With Opcenter APS, Polipak automated production scheduling, thus optimizing resource use and speeding up order fulfillment. The company replaced previously time-consuming and error-prone production planning with a flexible scheduling process. This accounts for the multistage nature of production, production constraints and resource and material availability, accounting for the timing of planned raw material deliveries.

Leveraging this APS system, Polipak also accelerated the planning process and enabled better capacity use. As a result, the company can fulfill orders faster and more efficiently. Simultaneously, using the implemented APS system enables flexible adjustment to changes in production, including fast response to machine failures or possible shortages of raw materials. Integration with other systems, such as enterprise resource planning (ERP), MES or the central dosing control system, enables a seamless flow of information, which translates into increased planning accuracy and allows the creation of realistic production scenarios.

“Using Opcenter thus supports strategic decision-making, enabling us to respond quickly to changing customer needs or circumstances,” says Migda. “By monitoring production in real time, we can assess the progress of the plan, which is key to maintaining high productivity and minimizing downtime.”

Using Opcenter for production quality management

Implementing Opcenter Execution Process, a Siemens MES solution, at Polipak was a key step towards using IT systems to support production process management. Opcenter Execution Process is the host system for managing production, together with other systems, including APS, ERP, warehouse management system (WMS), central dosing system and a computerized maintenance management system (CMMS). By maintaining interfaces, data sharing and bidirectional real-time communication, it creates an integrated production management environment.

Before implementing the MES, production monitoring and data management were fragmented and required a lot of manual work. With the system, Polipak can accurately track the production process in real time, which has significantly improved transparency and control over operations on the shop floor. The system collects and analyzes data from machines, allowing the company to identify potential problems before impacting production efficiency.

Using Opcenter also enables better synchronization of operational activities, from the receipt of raw materials through production to the final packaging and distribution of products. Integrating production data with the MES system provides full visibility throughout the production chain, resulting in higher product quality and minimal waste. Simultaneously, seamless procedures for receiving products, semifinished products and waste in the MES system allow Polipak to track performance and quality parameters in real time and react to problems as they arise, impacting their observed performance indicators.

Additionally, leveraging Opcenter Execution Process plays a key role in quality management, enabling monitoring of production parameters and early detection of deviations from quality standards. This reduces waste and complaints as well as supports the continual improvement of production processes.

Thanks to the compatibility and integration of the systems, Polipak benefits from a consistent flow of information, allowing it to optimize resource use and maintain a high level of production efficiency. Thus, implementing the MES system from Siemens has become the foundation of modern and sustainable production management at Polipak, supporting the company in achieving its strategic goals.

Instilling corporate sustainability

Implementing Siemens solutions at Polipak positively impacted the company’s operations, efficiency and sustainable growth. “Thanks to the advanced APS and MES systems from Siemens, we can accurately manage our resources and production processes, strengthening our competitiveness,” says Migda.

By increasingly improving resource management, Polipak increased the share of regranulate in production from 30 percent to as much as 90 percent over the years. This increase is the result of a strategic approach to raw materials, which includes not only buying regranulate and processing its own production waste but also buying clean postproduction waste from the market. Thus, waste that would previously have gone to a landfill is now used as a valuable raw material, supporting the company’s environmental performance. A key element of this process is the growing Regranulation Department.

The drive to increase the proportion of regranulates in production requires ensuring the right quality of raw materials. In response, Polipak envisaged implementing an automated waste washing plant by the end of this year, allowing the company to produce regranulate even from lower quality purchased waste.

These measures not only reduce production costs and support sustainability goals but also solidify Polipak’s position as a leader in eco-friendly foil packaging production. By integrating waste as raw materials, the company effectively minimizes its environmental footprint and promotes a more sustainable approach to production.

Polipak plans further comprehensive development and integration of digital systems, including the MES. Extending the functionality for the Roller Department, implementing the system in the Regranulation Department and extending the scope of the automation system to enable real-time parameter reading from machines not yet connected to the system will increase production control capabilities and enable comprehensive analysis of production parameters. Standardizing with Siemens solutions paves the way for a risk-free, less costly implementation process of functioning solutions in subsequent facilities of the Sarantis Group.

“Integrating Siemens solutions with the help of ASKOM has allowed us to increase production efficiency and monitor performance on an ongoing basis, which helps us be successful in today’s dynamic market,” says Migda.

Thanks to the advanced APS and MES systems from Siemens, we can accurately manage our resources and production processes, strengthening our competitiveness.