Optimizing the flow of product design information throughout the extended enterprise with Siemens Digital Industries Software technology

Teamcenter helps toolmaker Parpas Group more efficiently manage suppliers and accelerate product design and manufacture

Parpas Group

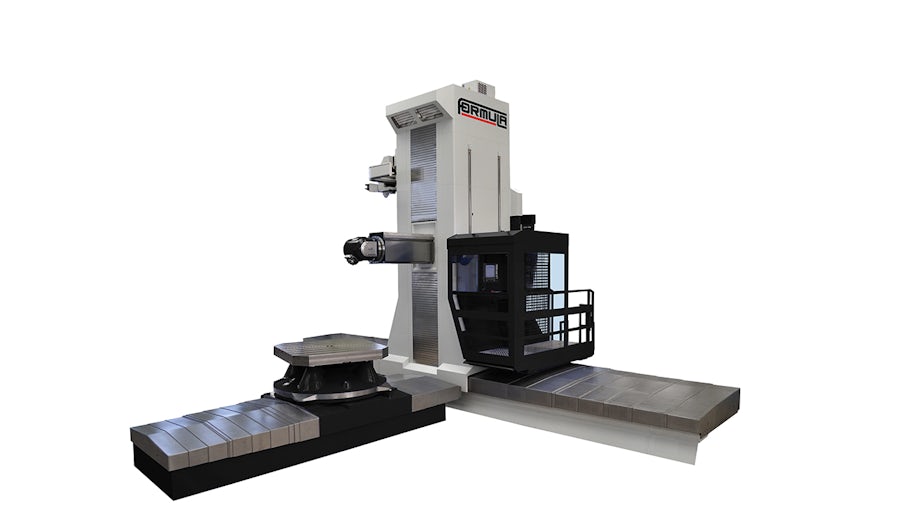

Parpas SpA specializes in milling and routing operations for large molds and dies, offering a line of medium to large milling machinery.

- Headquarters:

- Cadoneghe and Borgoricco, Italy

- Industry Sector:

- Aerospace & defense, Industrial machinery

With the aid of Teamcenter, we have high part and component re-use rates. We can apply advanced search functions not only to single details and parts, but also to entire operating modules, which can be re-used across different machines and orders.

Improving information flow to external suppliers

Parpas Group is two companies, Parpas SpA and OMV SpA. Together they manufacture milling and boring centers for the production of molds and dies, as well as mechanical components and large parts for the aerospace industry. The two companies have strong technical synergy, with fully integrated business and drawing codes. Parpas and OMV also use the same standard materials. Customers include Airbus, Boeing, Ferrari, Fiat, GE, General Motors, Lockheed Martin, McLaren, and Pratt & Whitney.

Production is on a build-to-order (BTO) basis. Engineers select from a portfolio of standard parts and components, which are then built to each customer’s specifications. “We always meet the demands of our customers, even if that means making radical changes to our machines,” says Michele Bacco, engineering department manager, Parpas.

A decade ago, Parpas Group began using DIAPASON enterprise resource planning (ERP) software with material requirements planning (MRP) capabilities. Around that same time, the group migrated from 2D computer-aided design (CAD) to 3D modeling software and implemented a product data management (PDM) system. After Parpas Group adopted Dassault Systèmes’ SolidWorks® software, management also identified the need to extend PDM functions outside the engineering department.

“Our business had grown and we needed to change our data management approach, extending access not only to other internal departments, but also to business partners,” notes Bacco. “The share of parts manufactured in house had been gradually decreasing over the years to the point where today we outsource 70 percent of our parts. We needed to manage our external suppliers more efficiently.”

Parpas management evaluated product lifecycle management (PLM) solutions according to functionality and performance. They chose Teamcenter® software from Siemens Digital Industries Software because of the demonstrated reliability of the solution. “Teamcenter was offered as a standard package by Tech-Value, a Siemens Digital Industries Software partner that has been supporting us for several years,” says Daniele Marcato, CED (consulting, engineering and development) Services. “The implementation of Teamcenter was smooth, especially the integration with SolidWorks.”

Unlike with the previous PDM system, the use of Teamcenter has helped Parpas streamline file management for all types of documents. The development process starts in engineering with the bill of materials (BOM) generated using Teamcenter. The BOM is then transferred to the ERP system to help start the production plan.

“Basically, we work according to orders driven by the Teamcenter BOM,” Bacco explains. “To compete in our market, we need to achieve the best result from our effort and resources, so we can avoid having to redesign from scratch each time. With the aid of Teamcenter, we have high part and component re-use rates. We can apply advanced search functions not only to single details and parts, but also to entire operating modules, which can be re-used across different machines and orders.”

Avoiding redesign results in significantly improved turnaround, another important benefit of using Teamcenter.

Tight integration and openness Teamcenter provides a window into DIAPASON and enables direct browsing and bi-directional integration with the ERP system. Teamcenter helps manage access permissions via web clients by helping Parpas leverage a specific function for managing preferred suppliers. “Teamcenter is currently accessible to approximately fifteen suppliers,” says Marcato. “They can log in via the web and download drawings and specifications for their operations. We have installed licenses for 17 designers and we have enabled visualization for people working in purchasing, production, on the plant floor, in the warehouse or quality control. We have been pushing hard to provide direct access so authorized people can view and print documents.”

In addition to CAD data generated using SolidWorks, all historical CAD resources were imported into Teamcenter, together with documentation generated by the engineering department. This includes purchase specifications, technical and sales documents, metrology reports, machining operations, assembly sequences and working instructions. This information is available in a variety of formats, including portable data format (PDF), Word and Excel® spreadsheet software, and picture files.

“A key benefit of using Teamcenter is being able to manage all types of documents easily,” says Bacco. “The solution supports the sharing of information among all the actors in our product development process. Efficient BOM management is critical because any delay or slowdown in the initial stages in the technical department affects all downstream operations. Now that we have extended the use of Teamcenter to the entire organization, the easy and efficient process of document sharing has driven more and more users to ask that the software be quickly implemented in other offices. Everyone appreciates the opportunity to view the information they need quickly to help them make decisions or find answers.”

Bacco and Marcato emphasize the stability of Teamcenter and the reliability of the system in terms of releases and revisions. Unlike with the company’s previous PDM system, using Teamcenter has significantly increased the use of workflows.

Teamcenter was implemented without disruption to daily business operations. As a result of efficient preparatory work with the gradual importation of data, users continued to work at a steady rate, generating a significant volume of vital information.

“The next step will be direct integration with our external technical offices,” says Marcato. “We expect further benefits from using Teamcenter in terms of the speed and efficiency of the web client for data access.”

A key benefit of using Teamcenter is being able to manage all types of documents easily. The solution supports the sharing of information among all the actors in our product development process.