Price and cost transparency help lead to higher profit margins

KLEINER relies on Teamcenter for improved cost estimation

KLEINER

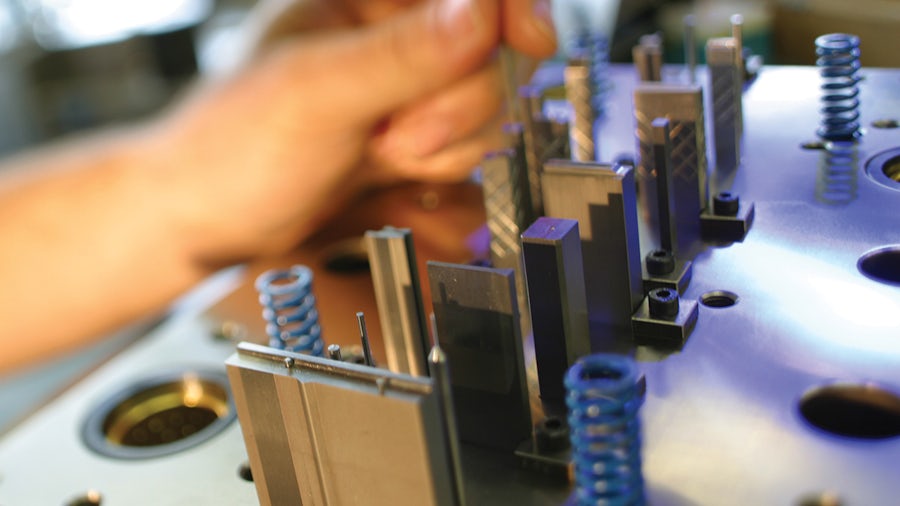

KLEINER GmbH is a leading developer and manufacturer of high-performance stamping tools and precision metal stampings.

- Headquarters:

- Pforzheim, Germany

- Industry Sector:

- Automotive & transportation

We are now able to react much more quickly on customers’ RFQs. We have increased efficiency by about 50 percent using Teamcenter.The Teamcenter tool costing solution is an open and flexible system. The data is well organized, and using the tool is transparent and user-friendly. We are excited by the modularity and simplicity.

Clear ideas about how a new costing tool should perform

KLEINER has reduced the costs of creating quotations by 30 percent using Teamcenter® software from product lifecycle management (PLM) specialist Siemens Digital Industries Software. Established in 1985, KLEINER produces high-performance cutting tools and precision stamping parts for the automotive, plastics, electrical, medical and electronics industries. The company’s product portfolio includes micro-stamped metal domes that replace traditional printed circuit boards. Design, prototyping, electrical discharge machining (EDM), grinding and milling are all performed by KLEINER personnel, enabling the company to tightly manage the high quality of its tools, which are fully assembled and tested in house.

High product quality and active cost management have always been important to the company. Each newly-produced tool undergoes a structured development process from concept through production. Accurate and timely delivery of proposals is a critical success factor for any toolmaker, and can mean the difference between success and failure during the bidding process.

In the past, KLEINER engineers manually prepared data based on their experience with the formerly-used enterprise resource planning (ERP) calculation tool. This resulted in time-consuming and error-prone calculations. The ERP solution provided only rudimentary reporting support, which limited the ability to obtain detailed cost breakdowns, including accurate cycle time calculations. This led to delays throughout the bidding process, which meant KLEINER had to invest more time than necessary to respond to customer price requests.

“The cost estimation of a big project with complex parts took weeks. Sometimes even longer,” notes Kevin Engel of Tool Technology at KLEINER. It wasn’t possible to gather all required information in a timely manner, which led to lost orders. The company urgently needed a powerful estimation tool to help speed up and standardize calculations.

The company’s engineers had clear ideas about how the new tool should perform. The new solution needed to contain all relevant information for the costing process within a central database, as well as provide the calculated hours by means of export and import mechanism to the company’s newly-introduced SAP® software for ERP. The costing solution also needed to represent the company’s tool technologies and manufacturing philosophy and provide an accessible database to enable collaboration. Access to current project data would save time and avoid errors.

Increasing profitability through more accurate costing

The decision to implement the Teamcenter tool costing solution was made easier by the wide range of functions that support the toolmaking estimation process. The solution contains predefined manufacturing processes, including calculation parameters, and can also support custom manufacturing technologies.

Another highlight is the forecasting functionality of Teamcenter. Using the software, a detailed breakdown of production hours can be created. If information is needed on additional incurred costs or sales overhead, the offer price is readily available. “We are now able to react much more quickly to customers’ requests for quotations. We have increased efficiency by about 50 percent using Teamcenter,” says Christian Hamann, KLEINER’s business unit manager, Tool Technology.

Using Teamcenter helps KLEINER’s engineers compare variants and uncover potential savings in the development of stamping tools. They can quickly determine if technically equivalent or even more sophisticated stamping tools can be used. “This way we can offer our customers significant cost reductions,” says Hamann. The re-use of data and calculation knowledge is a huge plus because customer requests are often similar. Changes usually arise only in the interface geometry. The data is created once and then is available to others. Hamann explains, “The Teamcenter tool costing solution is an open and flexible system. The data is well organized, and using the tool is transparent and user-friendly. We are excited by the modularity and simplicity.”

“Responsiveness is the key”

The company’s philosophy is straightforward: “Responsiveness is the key.” Most of KLEINER’s customers are looking for a trusted supplier. “The lowest price is not what is most important. It‘s about the best price, value and reliability,” says Hamann.

“Using the Teamcenter solution, we can provide our customers with an accurate quote within a few days by leveraging the data exchange between Teamcenter and SAP,” says Engel. This enables customers to make outsourcing decisions faster and more securely. KLEINER’s sales and engineering teams can use the solution to start pre-costing and manufacturing planning. Teamcenter also provides its engineers with significantly more cost transparency, which enables sustainable cost reductions and higher profit margins.

Many of the company’s customers use computer-aided design (CAD) software systems and can provide 3D models to KLEINER as the basis for determining costs. KLEINER’s engineers plan to add the 3D module of the Teamcenter tool costing solution, which helps determine the cost of a part or an assembly from a CAD model. With this additional new cost knowledge, the company will be able to make better design decisions even earlier, which will further shorten the offer preparation period.

The Teamcenter tool costing solution is an open and flexible system. The data is well organized, and using the tool is transparent and user-friendly. We are excited by the modularity and simplicity.