Using advanced technical features and flexible software licensing to rapidly scale up from a startup

Dynisma leverages Siemens Mechanical Design to go from producing basic prototypes to a holistic product portfolio in 36 months

Dynisma

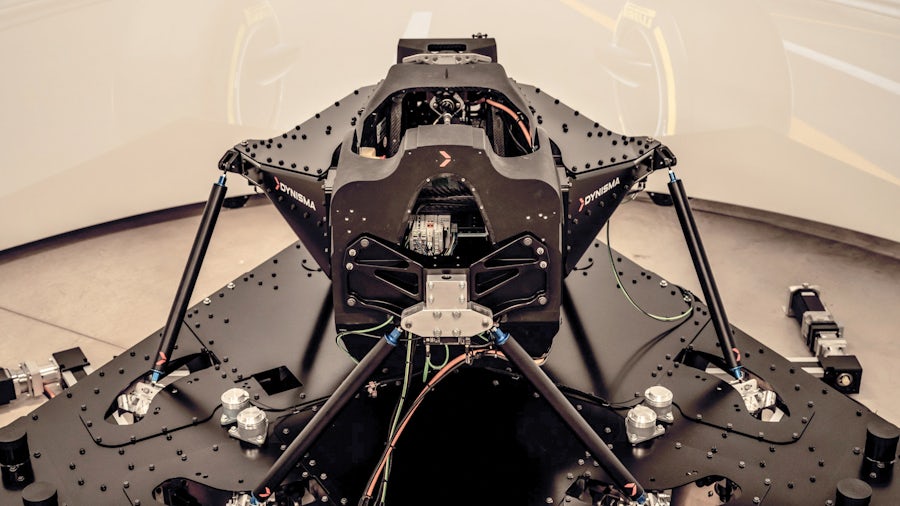

Dynisma is redefining the design, build and operation of motion simulation technology with highly disruptive products. Its technology targets the changing and expanding global markets for motion simulation, including motorsport, automotive, defense and aviation. With a team built on world class talent, it is equipped to consistently deliver excellence to all customers and partners.

- Headquarters:

- Winford, Bristol, United Kingdom

- Products:

- Teamcenter Integration for Solid Edge

- Industry Sector:

- Automotive & transportation

The Solid Edge for Startups program was appealing because it offers the full digitalization portfolio covering mechanical and electrical needs with high quality technical support.

Developing fresh, disruptive solutions for automotive and motorsport

In 2017, Ashley Warne, chief executive officer (CEO) and chief engineer of Dynisma Ltd., founded the United Kingdom-based driving simulator company after leading the in-house simulator development efforts for F1 at both McLaren and Ferrari. “Working in high pressure, excellence-led teams with significant resources instilled the belief that these efforts could be applied differently,” says Warne. “Access to the most advanced, high-fidelity, responsive motion generators that engineers could want should be made available to all.” At Dynisma, Warne is responsible for technical leadership and developing simulation concepts.

“Dynisma produces the most dynamic, responsive and scalable driving simulators in the world. Our team of world class engineers have taken on a fresh perspective and invented new solutions for automotive and motorsport,” states Warne.

Dynisma Motion Generators (DMGs) are fully immersive, offering the perfect solution for a range of audiences, such as motorsports teams that want to optimize driving and car performance or automotive manufacturers and suppliers that need advanced vehicle development and testing. The DMG delivers maximum bandwidth with minimum latency, which means that the simulator reacts very quickly to commands – in this case, response happens in 3 to 5 milliseconds. This is possible because the team co-designs software and mechanical engineering aims to remove every possible obstacle between the driver and the data.

DMGs are produced for all use cases in driving simulation for automotive and motorsport. The simulator also includes visuals, mock-up chassis, vehicle models and environment simulation. “DMGs are at least 50 percent better than any other comparable solution in the world and equally affordable,” states Warne.

Designing the DMG

“The development of DMGs always starts with embodying our unique selling points,” explains Matt Bell, head of mechanical engineering at Dynisma. “The process begins with a conceptual state, which gives the team a broad layout of the system before it is handed over to mechanical engineering. Then we identify and set all the key dimensions and components that will comprise the DMG. Once we feel like we have that arrangement correct, we tend to spread the work out to the rest of the team who will detail, draw and transform it into something that is producible. We also work with various suppliers who manufacture the structural parts – whether it is through formed metal work, computer numerical control (CNC) machined and 3D-printed components, or a composite structure.” Once the team figures this out, they have subassemblies or components come in for assembly and test.

“All our systems have very low latency,” summarizes Warne. “When we want a driver to feel that they are being moved – for example, from oversteer – this will happen in 3 to 5 milliseconds.” DMGs can be used to simulate any event like road texture, rumble strips, oversteer feedback and noise, vibration and harshness (NVH). Delays of milliseconds can have a huge impact in terms of the feedback given to the driver and their response.

Overcoming challenges as a startup

Like any startup, Warne and his team found the process of getting a business off the ground to be a challenging endeavor. “One critical success criterion is probably how fast you can bring your solution to the market,” Warne reflects. “That’s why we were looking right at the beginning for affordable yet advanced software to fulfil our needs in the mechanical design process of modeling and drafting, as well as a system level structural simulation solution.

After studying what was available on the market, Dynisma turned to Siemens Digital Industries Software and its Solid Edge for Startups program, which provides eligible startups with free access to a complete portfolio of product development software tools.

Along with one year of free Solid Edge® software, the program provides access to training resources, best practices and guidance from experts.

“When you are a fresh business with fresh investor funding, one of your primary focuses is making the capital you raise go as far as possible. So, the Solid Edge for Startups program was quite attractive at that time,” explains Warne. “It gave us this runway with a fixed cost for a certain amount of time, which provided flexibility in terms of licensing and enabled us to scale up as we took on new designers.”

As Dynisma applied for the Solid Edge for Startups program, they found the process to be painless. “We were able to quickly get the software licenses in place and integrate it with our cloud-based file sharing. From here, it was easy to get people up and working,” explains Bell. “When we were testing competitor options, some were more difficult to get and didn’t work properly a month in. With Siemens’ solution, the ease of setup and integration was a big influence on our decision.” By using Solid Edge, Dynisma’s onboarding licensing support process is now significantly faster compared to competitors. They can be up and running in days versus months.

Excellent support and advanced features

“The Solid Edge for Startups program was appealing because it offers the full digitalization portfolio covering mechanical and electrical needs with high quality technical support,” states Warne.

Dynisma has found Solid Edge to be the most useful for producing 3D models, rendering, drafting, simulation and for its built-in data management functionality, which enables them to manage new and existing files. The integration between applications allows Dynisma to significantly increase efficiency in their workflow. “The built-in data management system is a useful element that is not available in some other software packages,” states Bell. “We found the sheet metal modelling capabilities of Solid Edge to be excellent. It’s both powerful and user friendly enabling our new starts to quickly get productive with minimal rework.” Also, the assembly instructions are produced in Solid Edge. The team builds up the machine and moves through their verification and validation (V&V) activities and factory acceptance testing.

Siemens solution partners IC Blue and Emixa Industry Solutions also offered valuable support, making sure Dynisma got set up with licenses and received technology support during the implementation. Since then they have provided technical support and training for new team members at Dynisma. The quality of available technical support was one of the key reasons why the team chose the Siemens’ solution. “It was easy to get fast and reliable support from skilled people who could answer any question,” explains Bell.

Additionally, although Dynisma has scaled up and become more autonomous, they still benefit from the technical support, which enables them to discover and explore additional capabilities included in the software so they can become more proficient. “If we are experiencing an issue, the technical support team will set up an educational session and enable us to better understand how to overcome a problem,” states Bell.

Getting up to speed in days

The ease of onboarding and using Solid Edge has enabled Dynisma to rapidly bring team members up to speed and ultimately help them grow. “One way Solid Edge enables us to meet our design goals is that it is easy to pick up,” Bell explains. “We can find people who have used other Siemens packages, like NX, and they can quickly find their way around Solid Edge. Additionally, we have had several people come in who have used different packages who can pick up the software in a few days and produce useful work. This helps because it enables us to be responsive.

“It is now very easy to produce offers quickly, which also helped speed up our design and delivery processes – in the end the whole customer experience benefited from that shift.”

Going from startup to scaleup with Siemens Mechanical Design software

After the end of their startup phase, Dynisma expanded their product development capabilities to a new level by implementing Siemens Mechanical Design, which includes access to capabilities from both Solid Edge software and NX™. “Choosing this solution can enable us to grow while still being flexible enough to set the focus we want,” reports Bell. “After having an excellent experience with Solid Edge, the step to Siemens Mechanical Design was logical. It makes it easier to transfer in and out with NX files, improving interoperability with other software.”

The Siemens Mechanical Design software, including Solid Edge software and NX software, are part of the Siemens Xcelerator business platform of software, hardware and services.

The package itself provides a single source for all mechanical computer-aided design (MCAD) purchasing, licensing, training and service needs. “For us the main advantage of Siemens Mechanical Design besides agile licensing was to provide each designer or engineer with the features and functions needed for the specific development process they were assigned to. This was to maximize design capabilities while lowering total cost of ownership,” says Bell.

It is crucial for Dynisma to continuously produce conceptual models and develop detailed designs with them. Since it is a highly integrated package, they can do so. Along with the ability to pick it up quickly, there is a flexible licensing model where they can pay by the month in the case of a short-term contractor.

“As we grow, we plan on continuing to explore Siemens Mechanical Design, moving toward using more capabilities with the hybrid licenses,” states Bell. Looking further down the road, they will continue to broaden access to their groundbreaking technology, offering industry leading responsiveness in new sectors and markets.

For us the main advantage of Siemens Mechanical Design besides agile licensing was to provide each designer or engineer with the features and functions needed for the specific development process they were assigned to. This was to maximize design capabilities while lowering total cost of ownership.