Astronomic instruments maker uses simulation to save time and costs

Using Simcenter Femap helps ADS International move from virtual CAD prototypes to analysis and simulation

ADS International

ADS International is a private company working in the field of telescope, radio telescope and astronomic instruments design and production.

- Headquarters:

- Valmadrera, Lecco, Italy

- Products:

- Simcenter Femap/Nastran

- Industry Sector:

- Electronics, Semiconductor devices

Nastran models derived from Simcenter Femap are universally accepted, so interfacing with customers is never an issue.

Cut solving cycle time by 30 percent while leveraging parallel computing

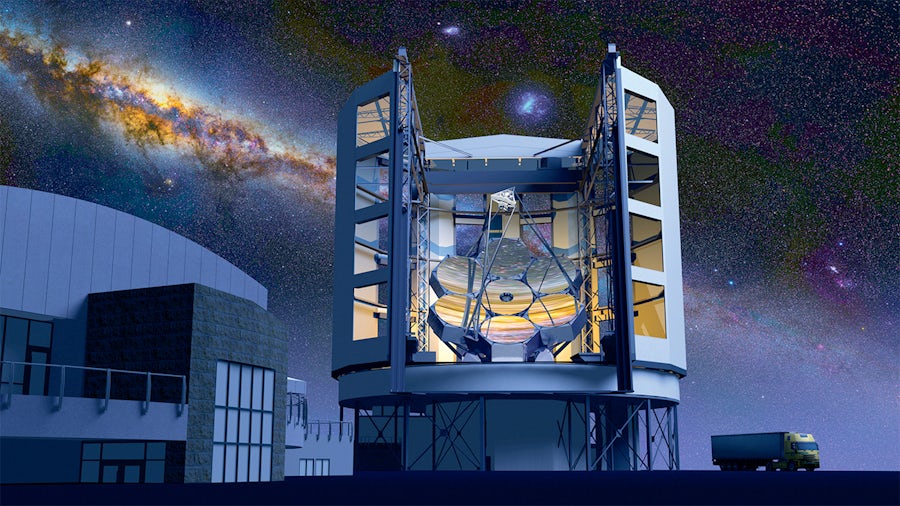

For nearly 30 years, ADS International (ADS) has been designing and building telescope, radio telescope and astronomic instruments, with two main product lines: adaptive optics and optics alignment systems. In a business in which each product is one of a kind, the company supports customers from preliminary study through execution, integration and final installation. ADS customers are universities, research centers and large international observatories, including the European Southern Observatory (ESO).

“Our specialty is adaptive optics developed in collaboration with Professor Piero Salinari of the Italian Institute of Astrophysics at the Observatory,” says systems engineer Paolo Lazzarini. “This technology corrects the distortions caused by atmospheric turbulence on images taken by ground-based telescopes, usually by means of deformable mirrors placed at the focal plane of the telescopes.” This system was initially introduced on telescopes located in the USA and Chile.

The most recent project is the implementation of adaptive optics (AO) correction directly on a telescope’s main optics secondary mirror. In the AO project, ADS is partnering with a team that includes an Italian company called Microgate (in charge of the electronic and adaptive optics control systems), the Italian Institute of Astrophysics (INAF) and Milan Polytechnic.

From prototype to simulation

The main challenge in the design of astronomic instruments is responding to unique demands within a reasonable time frame. “Each customer requests a one-of-a-kind product, which must be designed from scratch, for both digital simulation and mechanical construction,” Lazzarini says. “We normally use CAD (computer-aided design) software for 2D and 3D design. Then the workflows continue, using FEA (finite element analysis) simulation systems, numerical control (NC) and measuring machines.”

The ADS team needs to move rapidly from the virtual prototype stage to structural and thermal analysis and then digital simulation. For these activities, the company has been using ANSYS® software for computer-aided engineering (CAE).

Driven by the need to acquire new licenses, ADS decided to consider alternative FEA software systems. The company contacted Cosmos Italia Srl., a Siemens Digital Industries Software partner with expertise in CAE solutions. To support a cross-disciplinary approach to identify and develop customer-specific engineering solutions, Cosmos Italia recommended Siemens Digital Industries Software’s Simcenter Femap™ software, the CAD-independent pre- and postprocessor that utilizes Windows® software. After initial training, the Cosmos Italia team supported ADS with a hotline service that provides immediate feedback for specific issues.

“From the beginning, Simcenter Femap showed a profitable cost/benefit ratio,” notes Lazzarini. “Using Simcenter Femap, we can import geometry from any 3D format, helping us quickly switch from a virtual prototype to the FEM model with a consistently accurate import process.”

Once the finite element model (FEM) is available, ADS engineers can prepare a numerical simulation in just a few steps. “Simcenter Femap is efficient during the actual simulation because it enables us to leverage the potential of multi-core and multi-processor machines, at no additional cost, using ultra-fast solving,” says Lazzarini. “This was definitely a strong point in the selection of the software. With other solutions, the ability to share simulation tasks among several processors represents a separate capability, requiring additional expense. This capability and the intuitive graphical interface enable us to solve any analysis issue quickly and effectively.

“As a result of the use of parallel computing, we have cut processing time by 30 percent compared to using single processor systems. Furthermore, Nastran models derived from Simcenter Femap are universally accepted, so interfacing with customers is never an issue.”

The value of service

ADS adopted Simcenter Femap and accepted the challenge of revisiting ten years of experience and projects developed with ANSYS, which is still in use. “Simcenter Femap has given us excellent results,” says Lazzarini. “We have already expanded our use of this software, adding an advanced dynamics module to develop an interferometer for INAF. Using this new module, we can analyze the dynamic behavior of the interferometer, highlighting significant flaws in the previous design that were previously unknown, even to the manufacturer. We can identify them immediately with Simcenter Femap.“

During the first year of using Simcenter Femap, Lazzarini also participated with Siemens Digital Industries Software developers. “A few minor concerns we noticed in daily use were solved immediately,” he says, noting, “The new release of Simcenter Femap introduced significant enhancements, mainly to leverage a new generation of hardware, which enables us to optimize the management of large models. Today, Simcenter Femap is a primary resource for our company.”

Simcenter Femap is efficient during the actual simulation because it enables us to leverage the potential of multi-core and multiprocessor machines, at no additional cost using ultra-fast solving. This was definitely a strong point in the selection of the software.