Automaker uses Simcenter Amesim to optimize design of electrical systems early in the development cycle

Siemens Digital Industries Software solution enables Renault to reduce power consumption by improving energy management

Renault (Electrical Systems)

Renault is a French multi-national vehicle manufacturer that was established in 1899, and produces a range of cars and vans. Renault employs over 127,000 and has a presence in 128 countries.

- Hauptsitz:

- Guyancourt, France

- Produkte:

- Simcenter Amesim software

- Industriezweig:

- Automobil und Transport

“The overall objective is to help designers optimize the concept of the electrical systems earlier in the V development cycle, reducing physical tests and avoiding late design changes. Simcenter Amesim can also help reduce electrical power consumption by optimizing energy management; that’s to say the control laws implemented in the electronics module.

Achieving maximum energy efficiency

Electric power consumption in automobiles has risen significantly over the last decades. In the near future even greater electrical power requirements are expected. To limit the associated increase in fuel consumption and exhaust emissions, new strategies for the generation, storage, retrieval, distribution and consumption of electric power are needed. For example, the 1990 Renault Clio diesel needed at most 70-80 amperes (amps), whereas the 2006 Clio consumed almost double the amount, 120 to 150 amps. The challenge that arises now is how to control the power net to obtain maximum energy efficiency within the vehicle.

One of the main causes of increased electric consumption is the replacement of mechanical and hydraulic components with electrical devices. For example, enginedriven loads are replaced by electricallypowered versions. Think about all of that new technology. Today customers expect more and more comfort and safety features, such as power steering, climate control, heated seats and heated windscreens and mirrors. Altogether, this really adds to an automobile’s power requirements. With the increase in electrical and electronic content in vehicles, the maximum onboard electric power of all devices can reach several kilowatts (kW).

Overcoming limitations

The increase in electrical consumption affects the testing and simulation process. In the 1990s, statistical modeling was carried out to monitor various driving cycles in different weather conditions. These experiments could provide the mean value and peak request for electric power. During the development process, the designer could select the appropriate battery and alternator to meet the electric requirements of the vehicle. To be on the safe side, several physical tests had to be done in order to confirm the choice.

The trend to shorter development cycles and, therefore, performing fewer tests, really began early in the 21st century. At that time, Renault decided to replace actual testing by virtual validation for selected driving cycles. To minimize electric consumption, emphasis was placed on optimizing the battery and alternator selection by taking into account additional dynamics and using more precise models.

Renault developed a dedicated, in-house simulation tool using another modeling software application for virtual validations. It included temporal analysis to estimate the electrical power consumption during the driving cycle. Engineers could also define and validate alternator control strategies for better electrical energy management. Furthermore, they could estimate the battery lifetime in relation to charging/ discharging cycles and run worst-case scenario simulations, such as starting a cold engine or using an old battery.

Although this sounds like the ideal situation, Renault’s in-house simulation solution had its limitations. Simulation is just a means to an end, not an end in itself. Expertise in the engineering field remains a necessary element in the simulation process. Transitioning to new tools should be carefully managed throughout the process chain, including suppliers who need to supply critical parameters.

“The tool we developed was difficult to transfer to people who weren’t experts in simulation,” says Emmanuel Laurain, a modeling and simulation engineer in the Advanced Electronics Division of Renault.

“This was mainly due to an unintuitive graphical user interface (GUI), but also to numerical instability that could easily be solved by simulation specialists, but not by design engineers. Team-based work requires tools that are 100 percent reliable, user friendly and can allow an easy analysis of results.”

“Accurate, reliable and five times faster”

To overcome this, Renault benchmarked several simulation tools, some fully dedicated to electrical systems. In addition to the Simulink® environment and electronics simulation software, Simcenter Amesim™ software part of the Simcenter portfolio from product lifecycle management (PLM) specialist Siemens Digital Industries Software was selected because it is a true multi-domain simulation software package with an excellent numerical solver.

“It’s accurate, reliable and five times faster than our previous in-house tool for the same analysis,” says Ibrahim Mohand-Kaci, a mechatronics systems modeling engineer at the Advanced Electronics Division of Renault. ”We were already using Simcenter Amesim in other Renault departments. Now it will be much easier to share models, such as air conditioning and engines models, with other teams. It is fully compatible with our Simulink environment and hardware-in-the-loop platforms.”

Optimizing energy management

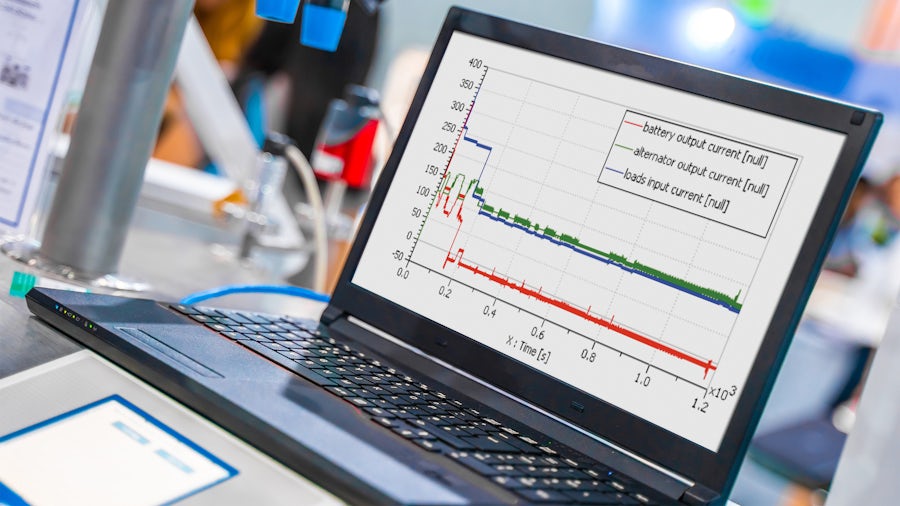

Today Simcenter Amesim is used at Renault for precision sizing of the battery and alternator, including the worst-case scenario startup validation. Control strategies are optimized as well. Consequently, advanced voltage control strategies can be evaluated. For example, when power is requested from the combustion engine, circuit voltage can be decreased.

“The overall objective is to help designers optimize the concept of the electrical systems earlier in the V development cycle, reducing physical tests and avoiding late design changes,” says Laurain. “Simcenter Amesim can also help reduce electrical power consumption by optimizing energy management; that’s to say the control laws implemented in the electronics module.”